27

Kwik Trim 53

Maintenance

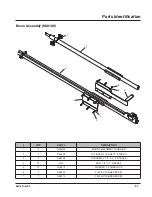

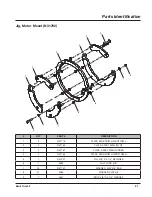

Boom

Care And Maintenance

NOTE:

A dirty boom does not shed rain as well and can

cause failure of di-electrical tests.

NOTE:

Do Not perform a boom di-electrical test while

the boom is wet as this can cause permanent

damage.

Park the machine on flat level surface, lower the dozer

blade and extend the boom to the operation position.

Lower boom fully to allow the water to drain out of the

boom.

Turn engine off and exit the machine.

NOTE:

Do Not use a pressure washer. High pressure

can cause water to diffuse through the fiberglass

fibers.

NOTE:

Abrasives and solvents cleaners are not

recommended as they can scratch or soften the

surface coatings.

Wash the boom by hand using soap and water only.

Electrical Conductivity Test

It is highly recommended that the boom be tested to

electrical conductivity every six months to insure operator

safety when working around high voltage.

This di-electric test should be conducted in accordance

with ANSI A92.2-2001 Category C.

Di-electric testing at over 1mA (1000 micro-amps) return

current can cause harm to the boom by causing the boom

to burn. If during the di-electric test, the return current is

close to 1000 micro-amps, stop the test immediately and

examine the boom for hot spots. Examine the boom for

any contamination such as dirt, moisture, sticks and other

debris. Let the boom cool and remove contamination.

NOTE:

Dirt or moisture can cause the boom to be burnt

beyond repair.

Boom Inspection And Repairs

Inspect the boom surface for cracks due to weather, age

or improper paint preparations as these can cause boom

failure.

NOTE:

Refinishing the exterior of the boom without

masking the interior can cause paint overspray

to settle on the inside. This overspray will trap

moisture and prevent water from beading on this

rough surface. The trapped moisture can lead to

failed di-electric tests.

NOTE:

Over loading the boom can cause stress cracks

and shorten the life of the boom. A single

overload can shorten service life by months or

years. A boom used as recommended should

remain in service for many years. A boom may

be overloaded by jamming it against trees or

putting it in a bind.

Cuts And Abrasions -

Cut and abrasions caused by

rubbing the boom on the side of trees etc. can weaken

the boom in the specific area of the damage. Consult

Loftness before attempting repair.

Sunshine And Ultraviolet Radiation -

Sunlight and UV

can damage an unpainted area of a boom causing. The

exposed area to look fuzzy as the fibers are exposed.

Repair surface scratches to seal out the sun and moisture

to prevent damage to the boom.

Improper Repairs -

Using substandard material and

improper repair procedures can result in boom damage.

There are two types of repairs:

1. Periodic surface repairs that involves the outside

coating.

2. Structural repairs that involve the boom itself.

Structural repairs should be referred to Loftness for

a case by case study.

Examples of structural repairs include cracks, cuts,

delamination and impact damage from tree limbs or

tools.

Summary of Contents for Kwik Trim 53

Page 2: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 12: ...Kwik Trim 53 ...

Page 18: ...6 Kwik Trim 53 ...

Page 24: ...12 Kwik Trim 53 ...

Page 42: ...30 Kwik Trim 53 ...

Page 43: ...31 Kwik Trim 53 PARTS IDENTIFICATION AND HYDRAULIC SCHEMATICS Parts Identification ...

Page 75: ...63 Kwik Trim 53 This page intentionally left blank Parts Identification ...

Page 93: ......