Owner’s Manual (Hydraulic Flail Mower)

N14800 3 - August, 2004

2

Maintenance

General Service Continued:

5) Apply a thread-locking compound to the nut and

torque to 75 ft. lbs.

removal and assembly procedures if necessary.

Belt Removal:

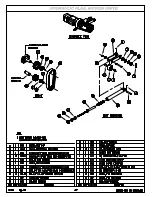

1) Refer to page 4-7 in Section 4 for an illustrated

parts listing.

2) Remove belt guard shield from left end of the

mower to expose the belt and its components.

3)

Unlock the 5/8” nuts on the threaded rod of

the belt tightener tube and thread them in to

relieve the spring tension on the belt.

4)

Remove the 1/2” nut and lock washer from the

1/2” bolt. Remove the bolt and pulley and the

two spacers.

5) Remove the belt.

6) Reverse the above steps for installation.

Pulley Removal:

1) Refer to page 4-7 in Section 4 for an illustrated

parts listing.

2) Remove the (2) screws from the taper lock

bushing of the rotor pulley.

3) Insert (1) screw into the threaded hole.

4)

Tighten screw until bushing grip is released. (If

excessively tight, lightly hammer face of pulley

using drift pin or sleeve).

NOTE:

Never hit

pulley directly with hammer.

5)

Replace the pulley by cleaning the shaft, bore of

bushing, outside of bushing and hub bore of all

oil, paint and dirt. File away any burrs.

6)

Insert bushing into hub. Match the hole pattern,

not threaded holes (each complete hole will be

threaded on one side only).

7) Apply a thread-locking compound to setscrews

and thread into the two opposing holes.

8) Position assembly on shaft and alternately torque

setscrews to 35 ft. lbs.

9) To increase gripping force, hammer face of

bushing using drift or sleeve. (Do not hit

bushing directly with hammer).

19) Re-torque screws after hammering.

11) Recheck screw torque after initial run-in, and

periodically thereafter, repeat steps 4, 5 & 6 if

loose.

12) Check alignment of the pulleys. Repeat pulley

CAUTION:

Excessive screw torque may

cause damage to the bushing

or sheave.

Rotor Removal

(Mower in Operating Position):

The belt and pulley should be removed with the

mower in operating position, but the procedures for

rotor removal and installation are greatly simplified

if the machine is turned upside down.

CAUTION:

If procedure is initiated with

mower in operating position,

proper lifting devices must

be used to lift and move rotor.

A mower rotor weighs

approximately 35 lbs./ft - i.e.,

a 90 inch mower rotor weighs

approximately 250 lbs.

Rotor Removal (Mower in Upside Down

Position):

This service section is written as if the mower is

upside down. If procedure is done with machine in

operating position, movable jacks will be needed to

support and move the rotor.

1)

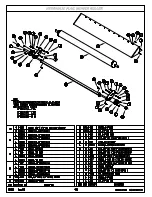

Refer to page 4-4 in Section 4 for an

illustrated parts listing.

2)

Attach a lifting device to both ends of

rotor, and apply a light tension.

3)

Loosen the set screws on the bearings.

4) Remove the (4) 1/2” nuts and lock

washers from the 1/2” bolts holding

the bearing to the anti-wrap plate on the

left hand side of the mower. Remove

the bearing. Remove the nuts and lock

washers on the (2) 1/2” bolts thru the

anti-wrap plate and the mower end

plate.

Summary of Contents for 48MH

Page 4: ......

Page 6: ......

Page 9: ...Section 1 Safety ...

Page 16: ......

Page 17: ...Section 2 Operating ...

Page 20: ......

Page 21: ...Section 3 Maintenance ...

Page 29: ...Section 4 Service Parts ...

Page 30: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......