33

Dispensing

5

5.2

Refilling the Product Reservoir (Replacing the Product Bottle)

Never completely empty the bottle in the reservoir! The entry of air into the product line

causes problems with dispensing.

☞

When air bubbles occur during dispensing, check if the product reservoir is empty.

●

For the dispensing of cyanacrylate adhesives, refill the product reservoir immediately since

air in the product line results in curing of the product!

When using an automatic reservoir, starts can no longer be initiated after the empty message.

This prevents the entry of air into the product line.

Before loosening the cover screw fasteners, the reservoir must be depressurized

(pressure-free)! (see Section 5.1)

●

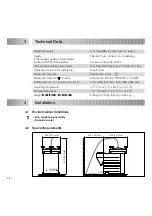

Loosen the cover screw fasteners

2

and remove

the cover

1

.

Product residue on the hose!

●

Place the cover

1

on the drip funnel.

●

Replace the empty product bottle or cartridge in the product reservoir with a full one.

☞

Automatic reservoir only:

●

Check that the product bottle inserted in the

bottle nesting block is pressed against the level

sensor (see Section 4.3).

●

Insert the product hose into the bottle and put on the cover

1

.

●

Uniformly tighten the cover screw fasteners

2

.

●

Set the depressurizing valve

5

to position

(pressurize).

●

On the 97102 controller, switch the reservoir to active with the button

.

On the 97103 controller, switch the reservoir to active with button

or

.

B

A

XS2/IN: Controller

XS2/OUT:Tank B

max. operating pressure

8 bar

operating temperature.

0 to +50C

volume:

3,5 Liter

Loctite (Ireland) Ltd.

Made in G

erm

any

XS2/IN

XS2/OUT

P in

Summary of Contents for 97105

Page 1: ...R R 97105 97106 97107 97108 ...

Page 2: ......