16

PC Program Instructions

6

Parameters

Cascade

Each burner control in the Cascade must be given a unique

address. This address can be changed by accessing parameter

4CC

. The Leader (top) burner (to which the thermostat/zone

control, system sensor, and system pump (if controlled by the

boiler) are connected) must be set to address 0. All the

Member burners must be given an address from 1 to 15. The

range of this parameter is 0 to 15. The default value is 0-1.

Master controlled through ModBus (Demand conf)

If the boiler or cascade is to operate based on its own inputs,

this must be set to No. The boiler can still be monitored

through ModBus with this parameter set to No. If the boiler

or cascade is to receive commands from ModBus, then this

must be set to Yes. The default setting is No.

Reload short time ModBus out of order

When the boiler or cascade is receiving commands from

ModBus, but using its own system supply and tank sensor

readings, the commands must be refreshed at least every 4

minutes by the building automation system. This is a fixed

timeout. If the boiler or cascade is receiving either the system

supply temperature or the tank temperature reading from the

building automation system, that information should be

refreshed more often. This parameter determines how often

this refresh must occur before the boiler or cascade goes into

its stand-alone mode. The time range for this parameter is 0

to 120 seconds. The default value is 10 seconds.

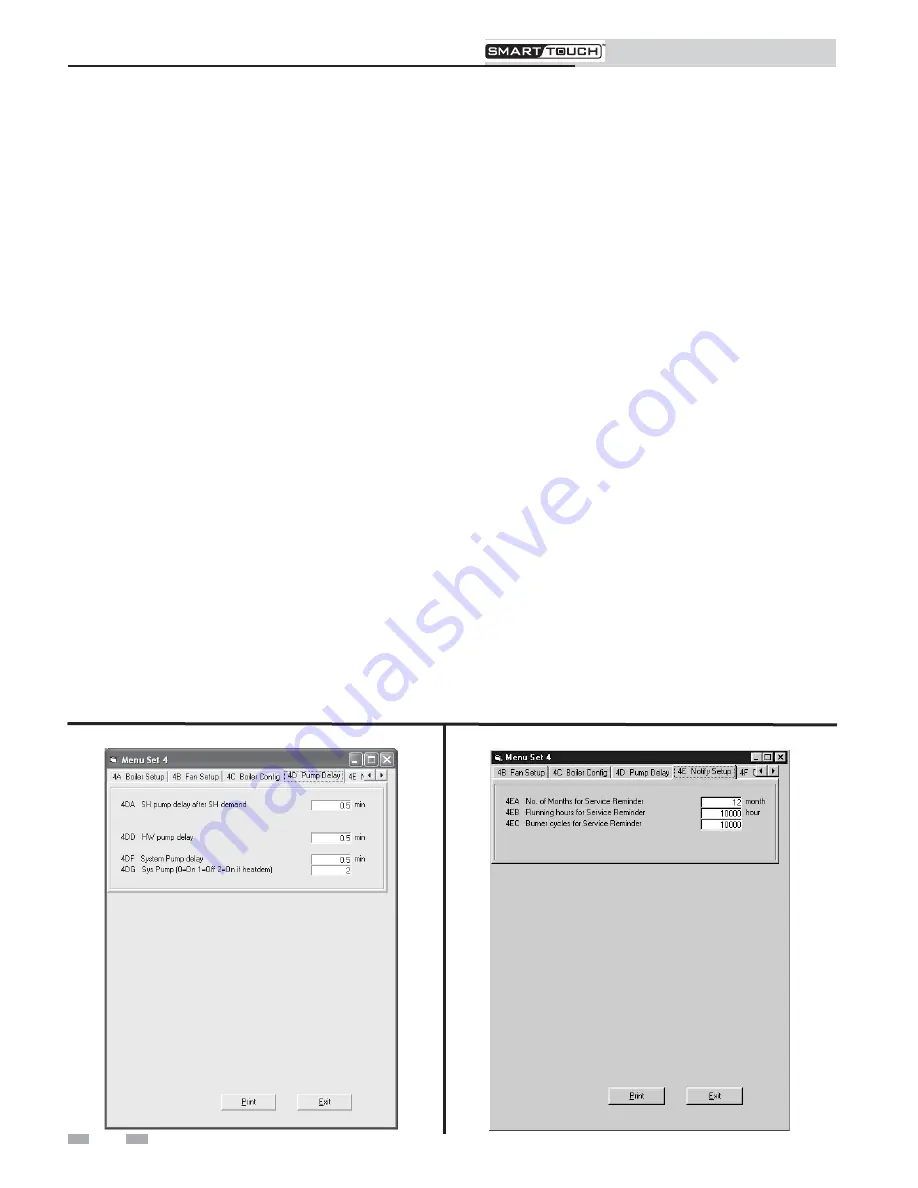

On the tabs at the top of the window, click on the tab labeled

4D Pump Delay

to set the delay time for the boiler, system,

and HW pumps (see FIG. 6-8 below).

Figure 6-8

Parameter Set 4D

SH pump delay after SH demand (Boiler Pump D)

This feature sets the length of time the boiler pump will run after

a SH demand has been satisfied. This parameter is adjustable by

accessing parameter

4DA

. The time range for this parameter is 0

minutes to 40 minutes. The default time is 30 seconds.

HW pump delay (HW Pump D)

This feature sets the length of time that the HW pump (if

connected) will run after a HW demand has been satisfied. This

parameter is adjustable by accessing parameter

4DB

. The time

range for this parameter is 0 minutes to 40 minutes. The default

time is 30 seconds.

System pump delay (Sys Pump D)

This feature sets the length of time the system pump (if

connected) will run after a SH demand has been satisfied. This

parameter is adjustable by accessing parameter

4DC

. The time

range for this parameter is 0 minutes to 40 minutes. The default

time is 30 seconds.

To set the parameters for Service Notification, click on the tab

labeled

4E Notify Setup

(see FIG. 6-9 below).

Sys Pump (Sys Pump mode)

The system pump can be set to operate different ways. The

operating mode can be adjusted by accessing parameter

4DG

.

When set to 0, the system pump will run continuously. When

set to 1, the system pump output will not activate. When set to

2, the system pump will turn on and off based on the space

heating call for heat. The system pump will always turn off

when the Outdoor Air Shutdown feature is active. The system

pump will always turn on when the freeze protection feature is

active. The default setting is 2.

Figure 6-9

Parameter Set 4E