Operating Manual

Tangential Rolling System T18F - T27F

22

www.lmt-fette.com

The axial rolling clearance is adjusted as follows: loosen the clamping screw (ET-37).

Place the supplied face spanner on the bushing (ET-13) and rotate in a clockwise

direction until the thread roll can no longer be rotated. Then rotate the bushing (ET-13)

back in a counterclockwise direction until the clamping screw (ET-37) is able to en-

gage in the next groove of the bushing (ET-13). Tighten the clamping screw (ET-37).

Check whether the thread roll can now easily be rotated again. The axial clearance of

the thread roll is now max. 0.05 mm (0.002 inch).

5.1.4

Functional testing

Proper operation of the roll head is ensured when the rolls can be rotated smoothly

and, if one roll is held tight, the other can be rotated to the inner side of the head. Here

the spring is extended in the equalizing gear. When the turned roll is released, it must

rotate back automatically to the initial position.

5.1.5

Adjusting the distance between the axes

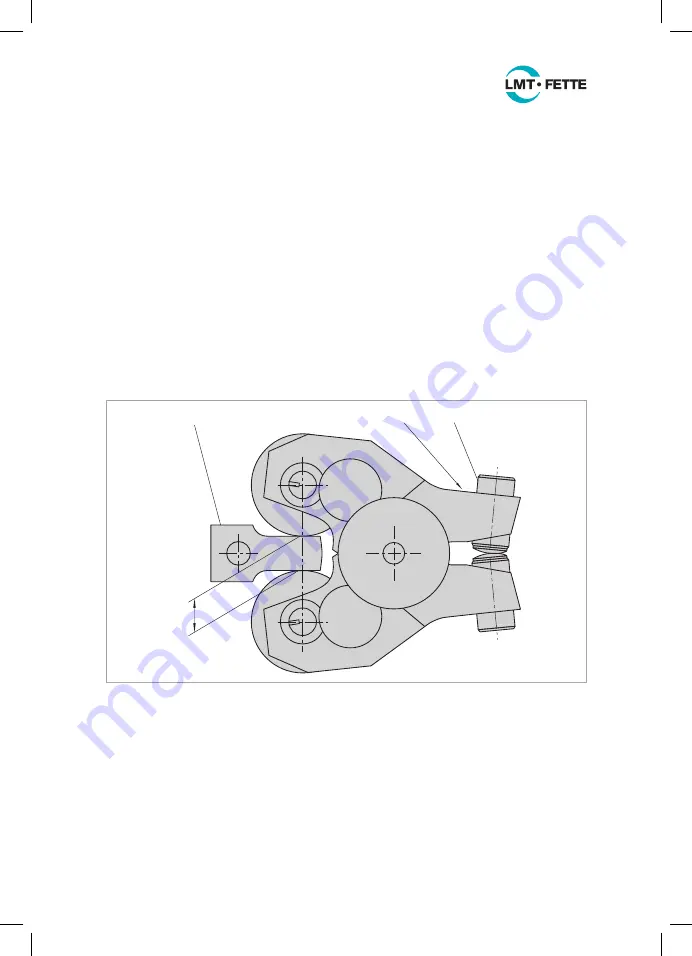

D

KW

ET-32

ET-28

ET-30

Figure 11: Adjusting the distance between the axes

The distance of the thread rolls – known as the distance between the axes – has to

be set to the required workpiece core dimension by adjusting the two set screws

(ET-30). The set screw (ET-28) is used to lock the set screw (ET-30). Loosen the set

screw (ET-28). The width D

KW

of the setting gauge (ET-32) roughly corresponds to the

minor diameter d

3

of the workpiece (see Figure 11). Adjust the set screws (ET-30) until

the setting gauge fits exactly between the rolls. Make sure that both set screws are

equally adjusted in the upper and lower part to ensure that the hinge is always opened

or closed symmetrically. When the distance between the axes has been adjusted, the

set screws (ET-28) must be tightened again.

LMT_Bedienungsanleitung_T18F_T27F_e.indd 22

02.08.11 17:40