Installation Guide Linear Motors

ENG

Page 10 / 32

P10-70-SSC / P10-70-SSC-D02

NTI AG / LinMot

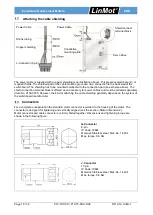

"Moving slider" installation

In a "moving slider" installation, the stator is fixed and the slider is the moving part.

The load, borne by a linear guide, is attached directly to the end of the slider. In order to compensate for

misalignment, spherical axial bearings consisting of spherical washers and conical seats (see the section

Slider mounting kits) are used to connect to the load. The mounting kit of slider and an oversized hole for the

screw make it possible to adjust a radial and angle offset.

Mounted payload with radial and angle offset.

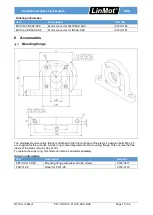

"Moving stator" installation

In "moving stator" applications, the slider is fixed and the stator is the moving part.

The load is attached to the stator, which is mounted on a linear guide. In order to avoid an overconstrained

bearing mount and compensate for alignment errors, the slider may be mounted on one end in a fixed

bearing with a spherical axial bearing. On the opposite end, the slider is mounted in a floating bearing.

Mounting kits are available for mounting the slider (see the section Slider mounting kits).

Stator

Floating bearing

Slider front end

Spherical washer and

conical seat

Slider back end

Linear bearing

Linear guide

Stator

Slider

Spherical

conical seat

Slider

back end

Linear bearing

Linear guide

Slider front end