INSTALLATIoN

WH45P

17

/42

rev 20-10

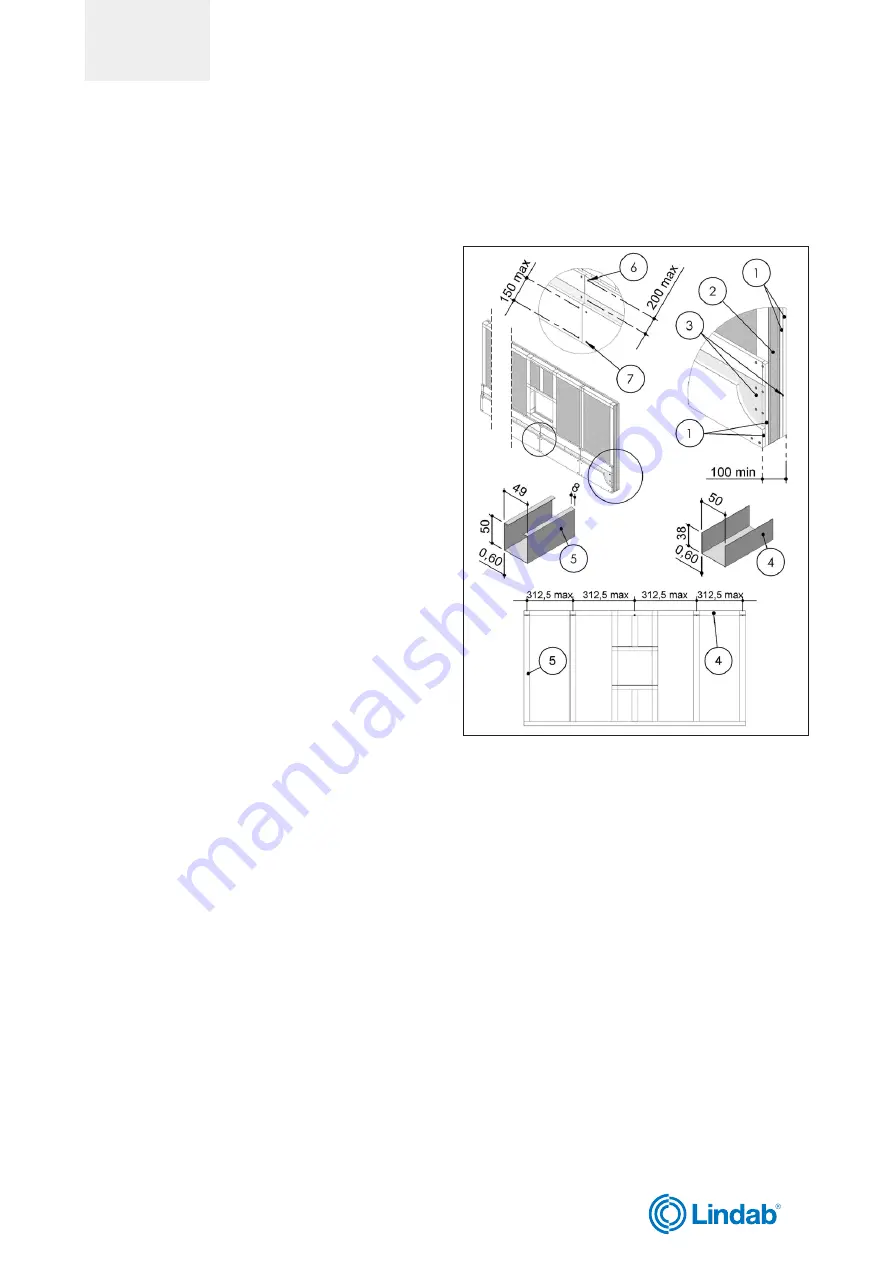

3.8.3.

Light plasterboard vertical walls with steel

reinforcement

During testing, light plasterboard walls have been used

with the following characteristics:

•

U-shaped horizontal metal frame (50 mm) and C-shaped

vertical frame (49 mm) made from 0,6 mm thick sheet

metal;

•

vertical profiles placed with a maximum spacing of 312,5

mm between each other;

•

reinforcement sheet;

•

Filling made of rock wool with density up to 100 kg/m³

(optional);

•

Each side is made from two plasterboard layers 12,5 mm

thick, unalinged to avoid alignment between the joints

of the layer above and below.

The following indications are given for the installation walls:

•

metal profiles minimum width: 49 mm;

•

metal profiles minimum thickness: 0,6 mm;

•

vertical profiles placed with a maximum spacing of

312,5mm between each other;

•

vertical profile fixing with selfthreading screws or by clin-

ching to the bottom horizontal profile and insertion in

the top horizontal profile;

•

profiles fixed using self-threading screws or by clinching

on every intersection.

•

installation of a frame around the damper with base and

height where shown in the installation instructions;

•

Filling made of rock wool with density up to 100 kg/m³

(optional);

•

each side is made from two plasterboard layers 12,5 mm

minumum thick, unalinged to avoid alignment between

the joints of the layer above and below.

•

the front plasterboards layers are fixed using long enou-

gh screws to pass through the lower plasterboard and

attach to the steel profile underneath.

1.

Plasterboard thickness 12,5 mm

2.

Rock wool density up to 100 kg/m³ (optional)

3.

Reinforcement sheet

4.

Horizontal U-shaped profile

5.

Vertical C-shaped profile

6.

Self-drilling screw Ø 3,5 X 25 mm

7.

Self-drilling screw Ø 3,5 X 35 mm

WH45P

17

We reserve the right to make changes without prior notice