Battery acid can burn eyes and skin:

Wear gloves and eye protection and be careful

when working near battery. Follow instructions

printed on battery.

1

When replacing, jumping, or otherwise connecting the

battery to the battery cables, the proper polarity must be

observed. Failure to observe the proper polarity could

result in damage to the charging circuit. The positive (+)

battery cable has a red boot on the cable.

2.

If the battery requires charging from an external charger,

disconnect the negative battery cable first and then the

positive battery cable before attaching the charger leads.

Failure to do so can result in damage to the internal charger

components. When reconnecting the cables, connect the

positive cable first and the negative cable last.

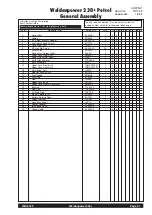

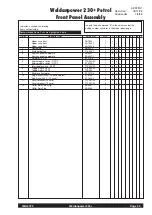

Hardware

Both English and Metric fasteners are used in this welder.

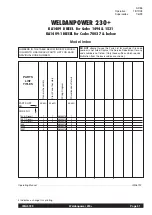

Engine Maintenance Parts

Page 16

Weldanpower 230+

IMA 572F

WARNING

Briggs & Stratton

Ruggerini

18hp Vanguard

RD201

Oil Filter

Briggs & Stratton

Ruggerini

492932

17524

Air Filter Element

Briggs & Stratton

394018

Air Filter Pre-Cleaner

Briggs & Stratton

272490

Fuel Filter

Briggs & Stratton

Ruggerini

493629

17519

Spark Plugs

Briggs & Stratton

(Resistor Type)

491055

Champion

RC12YC

HOW TO ORDER REPLACEMENT PARTS

To ensure that you receive the correct replacement part the following procedure should be followed:

1. Quote Serial Number and Code Number.

2. Quote the Description, Item Number and Parts List Number of the desired part. When ordering parts for items carrying brand names of

other companies, such as fan motors, drive shafts, etc., be sure to include the other company’s name and part number and other relevant

information.

3. Parts should be ordered from Lincoln, its offices or the nearest Authorised Field Service Shop. (The “Lincoln Service Directory” listing

these shops geographically is available on request.)

* “Hardware” in the Lincoln Parts Lists are not Lincoln stock items but can be obtained via the Field Service Shop network.

Component parts of assemblies such as stator coils or armature coils, etc., which require electrical testing or locating fixtures are not

considered replaceable items. This is to ensure that the customer receives parts which will keep the welder in the best operating condition.

BUY ONLY GENUINE REPAIR PARTS

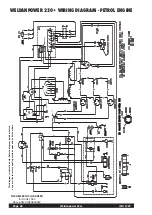

ELECTRIC SHOCK can kill

MOVING PARTS can injure

• Do not operate with panels open.

• Disconnect NEGATIVE (-) battery lead before servicing.

• Do not touch electrically live parts.

• Keep guards in place.

• Keep away from moving parts.

• Only qualified personnel should install, use or service this

equipment.

CAUTION

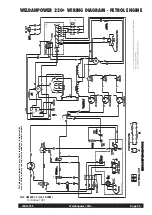

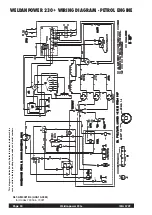

TROUBLESHOOTING

TROUBLE

CAUSE

WHAT TO DO

A.No welder or output power.

1. Check for brush wear and

1. Check brushes, replace or repeat as

proper contact with rotor.

necessary.

2. Open in miscellaneous leads.

2. Refer to wiring diagram and check

related leads.

3. Open lead in flashing or field

3. Refer to wiring diagram and check all

circuit.

related leads (200, 224, 200A, 200B,

201, 201A)

4. Faulty rotor.

4. Remove leads 200A and 219 and check

rotor resistance between slip rings. it

should be approximately 4-5 ohms.

5. Faulty Potentiometer (R1).

5. Replace with known good one.

6. Faulty stator Field winding.

6. Disconnect lead #9 at D2 and check

for continuity between leads #9 and #7.

7. Faulty Field rectifier (D2).

7. Replace with known good one.

.

8. Faulty P.C. Board.

8. Replace with known good one.