SP-170T

6

4

+

-

B-2

B-2

OPERATION

●

Reversible, dual groove drive roll, shipped ready

to feed .023"/.025" (0.6 mm) diameter wire. The

drive roll is easily reversed to feed .030" (0.8 mm)

diameter solid wire and .035" (0.9 mm) flux-cored

●

diameter wire. Optional drive roll included in .045"

(1.2 mm) Innershield

®

welding kit must be installed

to feed .045" (1.2 mm) flux-cored wire.

●

No external shielding gas is required when used

with Lincoln Innershield .035” (0,9 mm) NR

®

-211-

MP electrode.

●

Spindle accommodates both 8 in. (200 mm) diame-

ter and 4 in. (100 mm) diameter spools of wire.

●

Accepts optional Spot/Stitch Timer Kit.

WELDING CAPABILITY

The SP-170T is rated at 130 amps, 20 volts, at 20%

duty cycle on a ten minute basis. It is capable of high-

er output currents at lower duty cycles. .

LIMITATIONS

Arc Gouging cannot be performed with the SP-170T.

The SP-170T is not recommended for pipe thawing or

TIG welding.

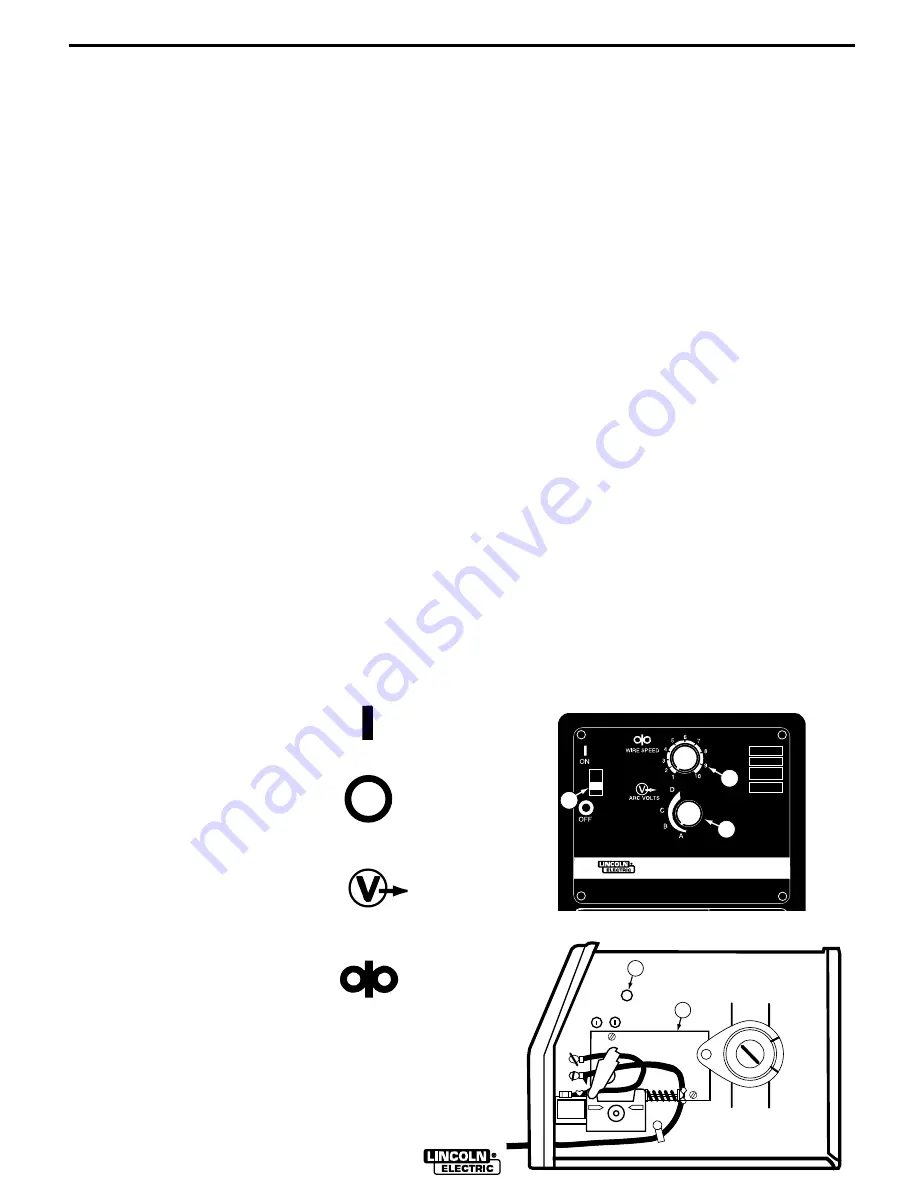

CONTROLS AND SETTINGS

See Figure B.1a.

1. Power ON/OFF Switch —

When the power is on the

fan motor will run and air will

be exhausted out the louvers

in the front of the machine.

The welding output and wire

feeder remain off until the

gun trigger is pressed.

2. Voltage Control — A 5-posi-

tion tap selector switch gives

full range adjustment of

power source output voltage.

Do not switch while welding.

3. Wire Speed Control —

Controls the wire feed speed

from 50 – 400 in/min (1.2 –

10.2 m/min). The control can

be preset on the dial to the

setting specified on the SP-

170T Application Chart

located on the inside of the

OFF

ON

ARC VOLTS

WIRE SPEED

4. Circuit Breaker – Protects machine from damage if

maximum output is exceeded. Button will extend

out when tripped (Manual reset) (See Figure B.1b).

5. Gun Trigger - Activates welding output, wire feed,

and gas solenoid operation. Releasing the trigger

deactivates welding and simultaneously activates

the “burnback” function so that the welding wire

does not stick in the weld puddle.

6. Optional K695-1 Spot/ Stitch Timer Kit Controls

(see ACCESSORIES section) - If present, replaces

Blank Panel Assembly located on the center panel

inside the case door:

Mode Switch - Selects between Spot, Stitch, or

Seam (normal welding) mode. Spot mode welds

for an adjustable length of time (set by Time

Control; see below) and then stops, whenever the

gun trigger is depressed and held. Stitch mode

cycles between welding and not welding for an

adjustable length of time (also set by Time Control)

while the gun trigger is depressed. In Seam mode

the machine will weld continuously while the gun

trigger is depressed. Releasing the gun trigger in

any of the three modes will interrupt welding imme-

diately.

Time Control - In Spot mode, controls spot mode

ON time between approximately .25 and 4.0 sec-

onds. In Stitch mode, controls stitch mode ON time

and OFF time simultaneously between .25 and 4.0

seconds each. This control is deactivated while in

Seam mode.(See Figure B.1b)

SP-170 T

3

2

1

FIGURE B.1a

FIGURE B.1b

Summary of Contents for SP-170T

Page 31: ...B 18 SP 170T B 18 APPLICATION CHART ...

Page 44: ...SP 170T NOTES ...