7

7

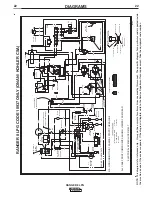

RANGER 8 LPG

• The stem of the cylinder valve and where the valve is attached

to the top of the cylinder.

• All other fittings on top of the fuel cylinder.

If growing bubbles appear, there is a leak. Re-tighten

connection or replace defective component. Retest to

make sure that there is no leak.

Leak test must be performed each time the fuel cylin-

der is replaced.

Always close the cylinder valve when the machine is

not being used.

The specification for aluminum lift truck cylinders are

shown below:

Capacity

Cylinder

Weight

Footring

LP-Gas

Volume

Empty

Outside

(LBS.)

(Cu. In.)

(LBS.)

Diameter

33.5

2219

22.5

9 3/8”

43.5

2873

25.5

9 3/8”

Note: The Ranger 8 LPG cannot be used with vapor

draw LP gas cylinders such as those used for

recreation vehicles, trailers, grilles, and boats.

Oil

The Ranger 8 is shipped with the engine crankcase filled

with SAE 10W-30 oil. Check the oil level before starting

the engine. If it is not up to the full mark on the dip stick,

add oil as required. Make certain that the oil filler cap is

tightened securely. Refer to the engine Owner’s Manual

for specific oil recommendations.

Pre-Operation Service

READ the engine operating and maintenance instruc-

tions supplied with this machine.

Fuel

A lift truck type coupler is provided on the supplied

fuel line for easy hand attachment to a lift truck type

LPG fuel cylinder. The fuel cylinder must meet D.O.T.

Specification 4E-240. The valve on the fuel cylinder

must be installed on the outlet marked “LIQUID”.

The engine will not develop full power if connected to

the vapor outlet.

Be certain that the cylinder valve is CLOSED before

attempting to attach the fuel supply hose coupler to the

cylinder. Connect the coupler to the fuel cylinder and

tighten by hand.

___________________________________________

After connecting the fuel supply to the supply cylinder,

open the valve on the fuel cylinder and leak test by

brushing a 50/50 soap and water solution on to the fol-

lowing connections:

• Both ends of the fuel hose where it enters the metal connector.

• The threaded fitting on the end of fuel hose attached to the

Ranger 8 LPG fuel shut off solenoid.

• The fuel hose coupler and the connection to the cylinder valve.

CAUTION

LPG

fuel can cause fire or explosion.

-

• All leak testing must be done in a well

ventilated area free from all potential

ignition sources.

• Keep sparks and flame away from machine and

LPG supply cylinder.

• Do not expose the LPG supply cylinder to temper-

atures exceeding 120°F (49°C).

• Do not weld on or near the LPG supply cylinder.

• Do not smoke or allow any potential ignition sources

near the LPG supply cylinder.

• Always be certain that the LPG supply cylinder is NOT

in the welding circuit. Do not allow either welding

cable to come in contact with the supply cylinder.

• Replace the fuel supply hose if there is excessive

abrasion, cracks or wear or if the hose is cut.

------------------------------------------------------------------------

WARNING

CAUTION

LUBRICATION SYSTEM CAPACITY

(INCLUDING FILTER)

Kohler CH20S - 2.0 Quarts (1.9 Liters)

Summary of Contents for RANGER 8 LPG

Page 32: ...NOTES RANGER 8 LPG ...

Page 33: ...NOTES RANGER 8 LPG ...

Page 34: ...NOTES RANGER 8 LPG ...