A-23

INSTALLATION

FUME EXTRACTION ARMS

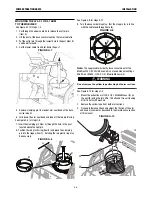

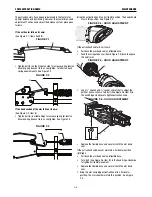

MoUntinG tHe eXtension arM

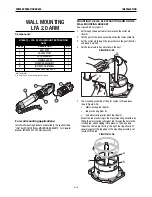

13.) Mount the (2) Arm Mounting Brackets

(Figure A.43, Item B) using the (2) 5/16-18 UNC, 5.00”

long bolts with nuts.

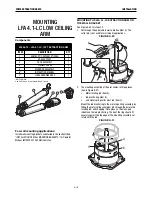

14). The Extraction Arm’s Rotating Hinge consists of three

pieces: The metal base swivel mount, red plastic ring

and clamping pin. Note: these items are packaged with

the LFA 3.1 and LFA 4.1 extraction arms.

See Figure A.42.

Mount the red plastic ring to the metal base swivel

mount by fitting the clamping pin through the hole in

the rotating rod, and snapping it into place on the

U-shaped indents on the red plastic ring. The lip of the

ring should fit securely against the top edge of the base

swivel mount, yet rotate with the rod.

The assembly should look like Item D in Figure A.43.

15.) Mount the Rotating Hinge (D) on the Arm Mounting

Brackets using the (4) 5/16-18UNC, 2.25” long, (4)

washers and (4) nuts. Make sure the cable hole is

positioned in the back, pointing toward the crane rail.

16.) Remove protective paper from the self-adhesive foam

seal and attach the foam seal onto the base swivel

mount. The foam which is sandwiched between the

base swivel mount and the tapered connection flange

will help to make the system airtight.

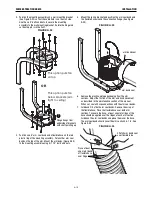

Mount the tapered connection flange (C) onto the base

swivel mount using (2) 5/16-18x1.75 HHCS, (2) 5/16-

18x2.50 HHCS, (6) washers and (4) nuts.

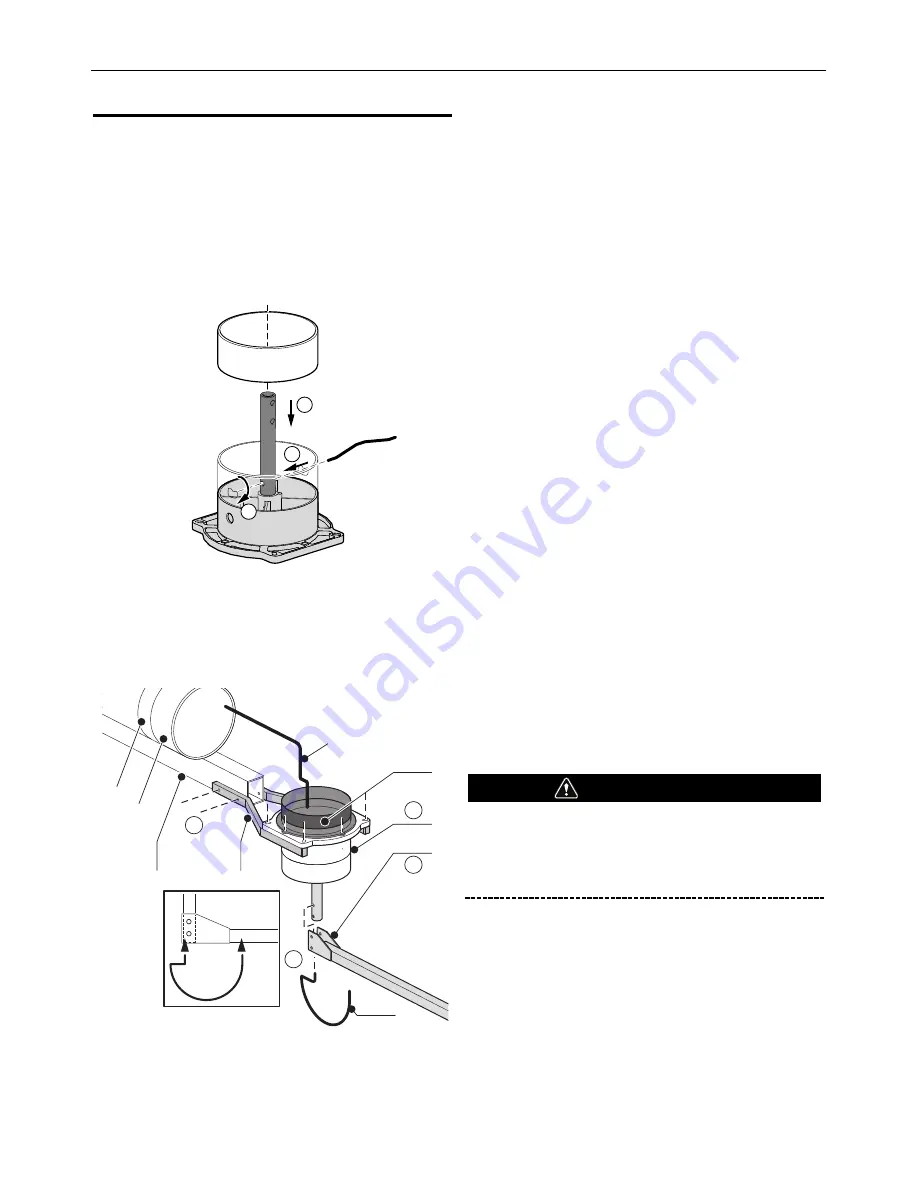

17.) Fold back 2/3 of the rubber seal.

18.) Cut the wrap of the flexible hose and place one end of

the flexible hose over the tube. To secure the hose, at

least one metal ring of the hose should be applied over

the ridges at the tube.

19.) Fold back the rubber seal and place it over the hose.

The rubber seal should cover 0.5 to 1 inch of the tube.

20.) Place the Distance Spring (K) in the clamping bush in

the middle section of the base swivel mount. Feed the

other end of the Distance Spring into the open end of

the flexible hose.

21.) Secure end of hose to inlet ring with hose clamp.

22.) Place a rubber seal over the lower part of the tapered

connection flange (D) and fold back 2/3 of the rubber

seal.

23.) Place the lose end of the flexible hose over the lower

part of the tapered connection flange and secure the

hose with rubber seal.

24.) Turn the hinge rod so the long side of the stop pin at its

base points away from the wall, and mount the hanging

adapter (Fig. A.42, Item E) to the hinge rod using the (2)

2.25” bolts with nuts.

25.) Mount the spring bracket (Figure A.42, Item F) into the

two holes as shown.

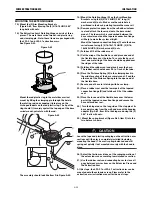

Leave the tape and plastic packaging on the extraction arm

sections until the arm is completely installed (including

mounting the hood). The arm is spring-balanced and will

spring out quickly if not mounted securely with the hood in

place.

26.) Adjust the friction resistance of the swinging motion of

the extension crane according to maintenance section.

27.) Use the rubber seals and connecting hoses to close all

gaps between arm sections on the Extension Crane and

the Extraction Arm.

At this stage, the LFA 3.1 or LFA 4.1 extraction arm can be

mounted onto the extension crane. Please refer to the

extraction arm instruction manual for the next steps.

CAUTION

2

1

3

Figure A.42

C

D

E

B

A

F

1

4

2

3

I

J

K

Figure A.43

Summary of Contents for K1655-10-LTA 2.0

Page 43: ...ii THIS PAGE INTENTIONALLY LEFT BLANK...

Page 61: ...P 968 C jpg LFA 4 1 K2633 7 General Assembly LFA 4 1 K2633 7 14 13...

Page 63: ...P 969 C jpg LFA 4 1 K2633 8 General Assembly LFA 4 1 K2633 8 14 13...

Page 64: ...ii THIS PAGE INTENTIONALLY LEFT BLANK...