16

7.2

Check of the BFK 457-08

The air gap between the magnetic coil (1) and the anchor plate (2) should be checked once a year or if the brake

distance is too long. If the air gap is too large, the brake has to be replaced.

Assembly instructions:

1. Remove the fan cover (4). (Disconnect mains supply before!)

2. Push the thickness gauge between magnetic body (1) and anchor plate (2).

3. Check the air gap S

L

. If the maximum air gap of 0.5 mm is reached the brake has to be scraped and replaced by

a new one.

4. Screw on the fan cover (4).

5.

Function check:

The nominal load must be held securely and braked securely out of motion. The braking should be smoothly.

The brake must be replaced, if the rotor has a thickness of 5.5 mm.

7.3

Assembly of the DC disk brake

Assembly instructions:

1.

Press the hub onto the shaft.

2.

Secure the hub by use of a retaining ring against axial movement.

3.

Assemble DC disk brake to the hub.

4.

Screw the DC disk brake on the gear cover by use of the hexagon screws 3x M5.

5.

Tighten the screws with equivalent torque of 5.5 Nm.

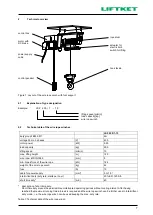

Assembly of the hub onto the shaft

Assembly of the DC disk brake on

the gear cover

Tightening by a torque wrench

Figure 12: Assembly of the DC disk brake

Attention!

For order of spare parts, the complete type designation has to be submitted!

The disassembly should be done in inverted order!

7.4

Faults on the DC disk brake

Troubleshooting and fault elimination

Faults

Causes

Remedy

brake does not

release; air gap is not

zero

coil has contact to ground or

between the windings

Replace the DC disk brake.

wiring wrong or defect

Check wiring diagram and correct wiring

rectifier wrong or defect

Compare wiring of the bridge at rectifier with wiring diagram.

Measure DC-voltage between terminals 5 and 6.

If differences occur change the rectifier.

air gap too large

Replace the DC disk brake.

Table 3: Troubleshooting and fault elimination

If the rectifier defects occur repeatedly, the brake shall be replaced even if no winding short circuit can be detected.

Defect may occur only in warm operating condition.

gear cover

hub

retaining ring

DC disk hub

brake