13

6

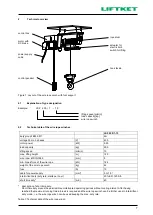

Maintenance

All maintenance work must be carried out by trained specialists and may only be carried out if the wire

rope winch is unloaded and the mains is switched off so that the power supply is disconnected.

6.1

Test and maintenance works

The operation of the wire rope winch is covered by the DGVU Vorschrift 54 §

23 „Winches, lifts and pulleys“

regulations in Germany. The winch has to be inspected by a trained specialist before first use and after any major

changes. The design and method of manufacturing of the wire rope winch has received a general approval. The

dynamic and static tests are accomplished acc. to EC Machinery Directive by manufacturer.

The suspension points and the unit itself have to undergo a yearly safety check by a trained person. Trained

specialists are highly qualified specialist personnel or the manufacturer’s after-sales service personnel.

If the hoist is in heavy use (two or three shifts, high percentage of work with nominal load, dusty or high temperature

environment) this maintenance work should be done more frequently.

All maintenance work must be entered in the crane log book included in the delivery.

check

daily

3 months

yearly

visual check of the whole equipment

●

function check

•

brake: braking distance under load

•

limit switch: switch-off up, down

•

wire rope: squeezed, bent, dented and broken wires

(DIN 15020 Bl.2), rust, condition of the windings

●

●

●

maintenance / adjustment

•

brake: control of the air gap

●

lubrication of the wire rope

●

universal check

•

screw fittings

•

safety elements

•

hook tackle / load hook

●

●

●

electrical control

•

power supply cable: squeezed, pulled off, condition of

insulation

•

control pendant: damages, proper function, emergency

stop and all electric accessories

•

control box: damages, sealing

•

check of limit switch

●

●

●

●

Table 2: Test and maintenance works