5

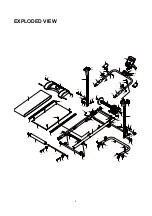

PARTS LIST

No.

Description

Qty No.

Description

Qty

001 Main Frame

1 021

Hexagon Socket Pan Head Cap

Bolt M8x40

2

002 Base Tube

1 022 Extension Sensor Wire (1000 mm)

1

003 Left Upright Tube

1 023 Nylon Nut M8

5

004 Right Upright Tube

1 024 Sensor with Wire (210 mm)

1

005 Handlebar Ø28

1 025 Hand Pulse Sensor

2

006 Magnet Bracket

1 026

Hand Pulse Sensor Wire

(800 mm)

2

007 Front Roller Ø42x417.5

1 027

Cross Recessed Pan Head

Tapping Screw ST4.2x19

2

008 Front Roller Axle Ø12x450

1 028 Spring

1

009 Rear Roller Ø60x444

1 029 Rectangular End Cap (

□

30x15)

2

010 Rear Roller Axle Ø12x496

1 030 Handlebar Foam Grip

2

011

Hexagon Socket Cheese Head

Cap Bolt M6x75

2 031 Wire Clip

1

012 Washer Ø13xØ6.2

2 032 Main Frame Rear End Cap

2

013

Cross Recessed Pan Head Bolt

M6x20

1 033 Plastic Washer Ø23.5xØ12.2x4

4

014

Cross Recessed Pan Head

Drilling Screws with Tapping

Screw Thread ST5.5x25

6 034 Handlebar Cover

2

015 Lock Knob M8x60

1 035 Side Rail (975Lx30W)

2

016

Cross Recessed Countersunk

Head Drilling Screws with

Tapping Screw Thread M3x10

2 036

Incline Adjustment Frame Round

End Cap Ø33xØ25x25

2

017

Extension Sensor Wire I

(650 mm)

1 037

Main Frame Front End Cap

(D50.8x41.4)

2

018

Hexagon Socket Pan Head Cap

Bolt M8x45

5 038 Plastic Cover

1

019

Cross Recessed Pan Head Bolt

M5x15

1 039 Transport Wheel Ø48xØ8.2x16.5

2

020 Nut M6

1 040 Rubber Pad

4