Introduction to STS2 Operations

59

8.2.4 Bypass

The static transfer switch can be manually bypassed to allow the power from a source to directly flow

to the output load. This bypass allows the unit’s electronics to be serviced without dangerous voltages

being present.

The STS2 includes key-interlocked maintenance bypass breakers that allow either input source’s elec-

tronics to be bypassed for maintenance without interruption of power to the load. The maintenance

bypass allows all electronics to be isolated from the input, output, and bypass connections. Bypass

instructions are available from the touch screen and are discussed later in this manual.

8.3

Operator Controls

The STS2 is equipped with an interface to configure and monitor the unit either locally or remotely.

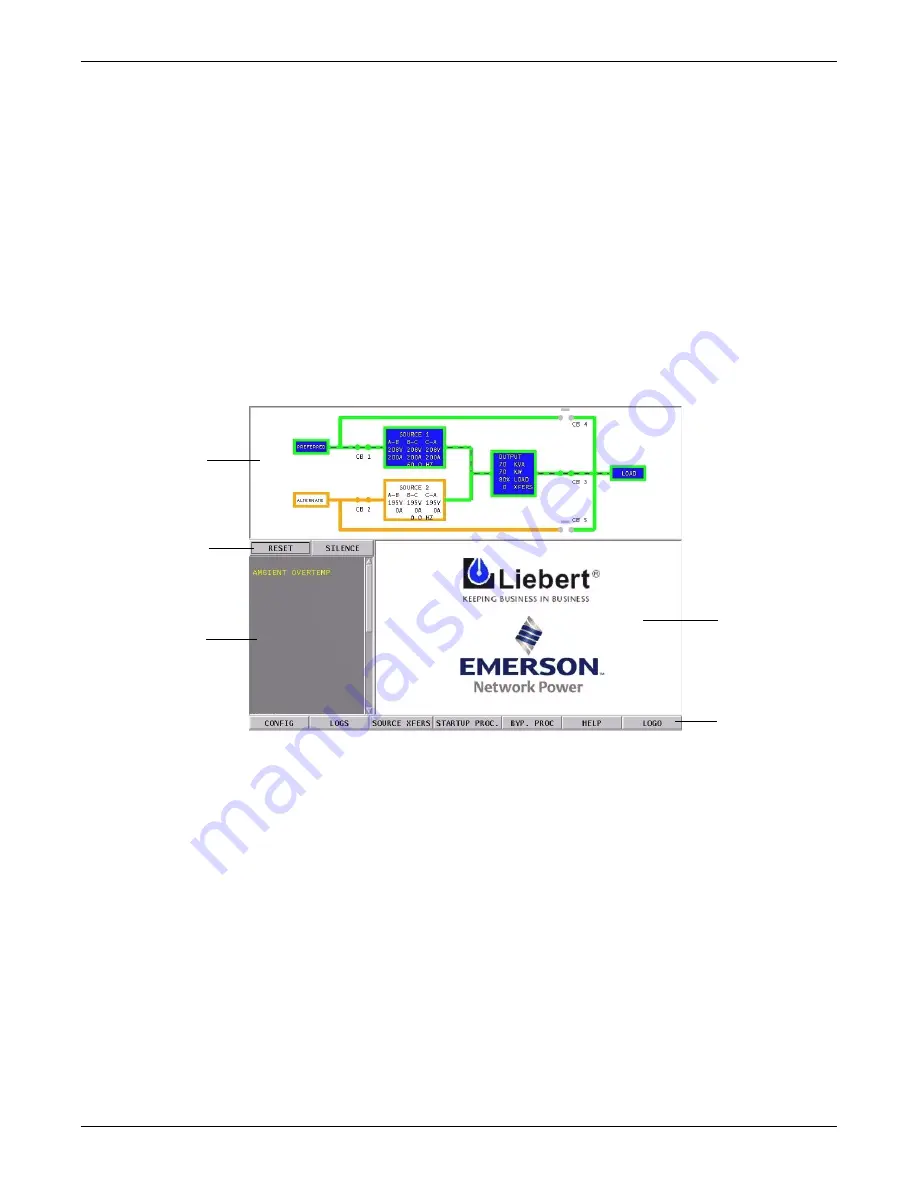

The Color Graphical Display is a touch screen LCD that provides a color diagram (Mimic) that dis-

plays the current status of the unit. System parameters are displayed and help is available to define

events. See

Figure 45

below and

Figure 31

. The touch screen menus allow the operator to initiate

source transfers, view event and history logs, and view bypass and other operational instructions.

Figure 45 STS2 touch screen display

Touch screen control buttons allow you to reset alarms, silence the audible alarm, review configura-

tions, event and history logs, preferred source, startup and bypass procedures, and the help menu.

Qualified personnel, with a password, can use these menus to configure parameters, select a pre-

ferred source, and do manual source transfers.

LED display units do not have the color LCD display. Instead of the touch screen, these units are

monitored by a series of LEDs and controlled by a series of push buttons.

Both units can be accessed from a terminal, or a PC running terminal emulation software, that is

attached to the unit. Through the RS-232 access, you can monitor and configure the unit, plus

remotely select a preferred source. See

12.1 - Using the RS-232 Port

on page 76 for instructions on

using the RS-232 interface.

Mimic

Event Display

Event controls

Display Panel

and

Help Screen

Menu Options

Summary of Contents for POWER PROTECTION STATIC TRANSFER SWITCH

Page 1: ...POWER PROTECTION STATIC TRANSFER SWITCH 2 USER MANUAL 100 1000 Amp 50 60 Hz...

Page 2: ......

Page 148: ...Maintenance 140 Channel 8 Channel 9 Channel 10 PRB Notes...

Page 150: ...Maintenance 142...

Page 151: ......