4-3

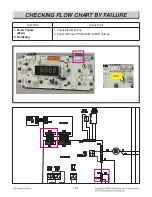

Components

Test procedures

Results

Oven (safety) valve

1. Refer to page 3-21 for servicing procedure.

2. Measure the resistance after cooling down.

(Multiple meter scale : R x 1)

Normal: Approximately

1 ~ 3 Ω

If not replace

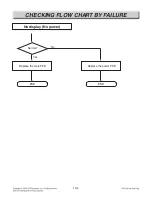

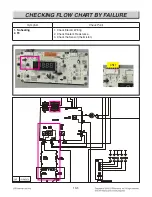

Ignition switch

1. Refer to page 3-6~3-7 for servicing procedure.

2. Measure the resistance by rotating the cam of

each switch slowly.

(Multiple meter scale : R x 1)

approximately

40° ~ 80°

other

Infinite

Continuity

Upside

Downside

40˚

80˚