- 14 -

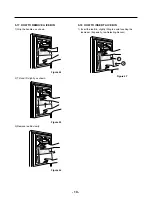

3-19 HOW TO REMOVE AND REINSTALL THE PULLOUT DRAWER

3-19-1 Follow Steps to Remove

Step 1) Open the freezer door.

Step 2) Remove the lower basket.

Step 3) Remove 2 screws one on each side of the guide

rails.

Step 4) Removal of the freezer door is done by lifting clear

of the rail support. Fully extend both rails.

Step 5) First: Remove the gear from the left side first by releasing the tab behind the gear, place a screwdriver between the

gear and the tab and pull up on the gear.

Second: Remove the center rail.

Third: Remove the gear from the right side by following the same steps for the left side.

NOTE: THIS TAB MUST BE PUSHED IN TO RELEASE THE GEAR.

Figure 48

Figure 49

Figure 51

Figure 50

Figure 52

Summary of Contents for LFX25978 Series

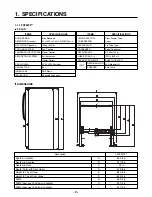

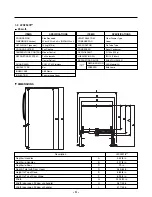

Page 19: ... 19 5 CIRCUIT DIAGRAM LFX28978 ...

Page 20: ... 20 LFX25978 ...