10

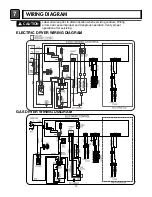

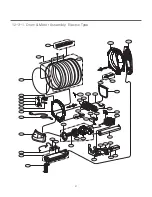

CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS)

28

Natural Gas mode is set. Propane Gas Orifice is on sale as a Service

Part to authorized servicers only.

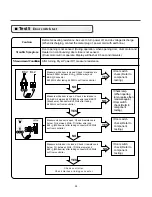

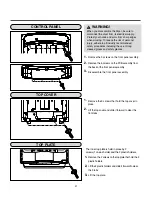

STEP 1 : VALVE SETTING

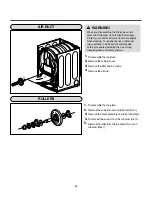

STEP 2 : ORIFICE CHANGE

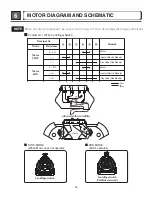

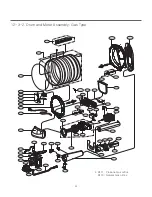

Natural Gas

Propane Gas

4948EL4001B

4948EL4002C

Kit contents:

Orifice (Dia. = 1.47mm, for Propane Gas)

Conversion Label

Instruction Sheet

NCU

PCK

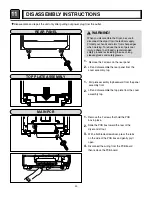

Remove 2 screws.

Disassemble the pipe assembly.

Replace Natural Gas orifice with Propane Gas orifice.

Opened

Closed

Orifice

Initially,

Changing orifices and gas valve adjustments improperly can result in an

explosion and/or fire. Conversion must be made by a qualified technician.

!

Warning

The burner is set for natural gas at the factory. The propane orifice

conversion kit is sold as a service part to autherized servicers only.

Part numbers are shown below.

Full open

Adjustment screw

Close

Adjustment screw