16

INSTALLATION AND MAINTENANCE

CPLS drip-proof 3-phase induction motors

4240 en - 2014.09 / b

LEROY-SOMER

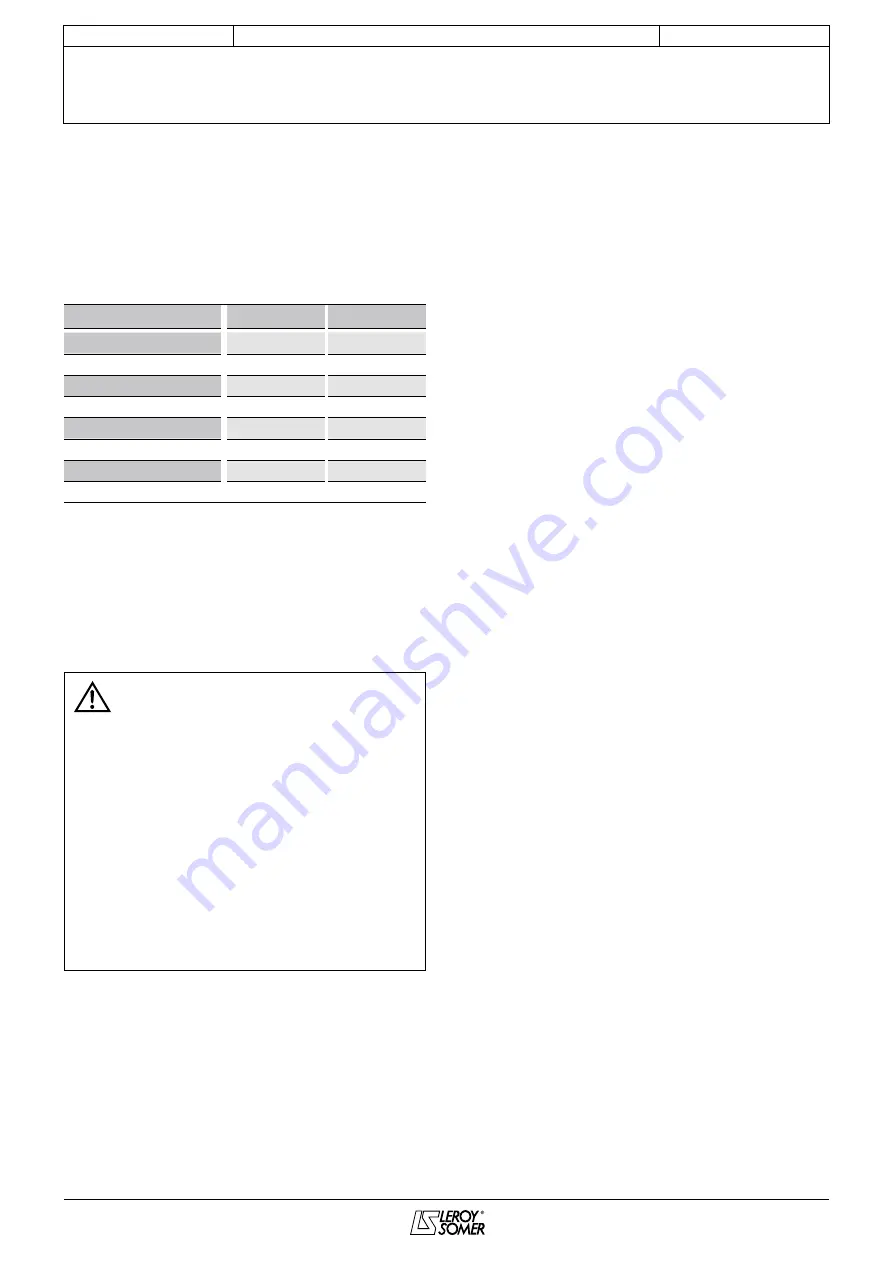

Quantity of grease

As the bearings are pre-lubricated in the factory, no greasing

is needed during commissioning, unless the motor has been

stored for a long time (see section 1.2 - Storage).

During the

first greasing undertaken by the customer or if

the grease inlet pipes have been cleaned

, a slighter larger

quantity of grease should be added in order to ensure that the

new grease reaches the bearing.

Motor

1

st

greasing

2

nd

greasing

CPLS 112

14 g

11 g

CPLS 132

18 g

15 g

CPLS 160 Std, HV1, HV2

25 g

20 g

CPLS 160 HV3

16 g

11 g

CPLS 200 Std, HV1, HV2

45 g

40 g

CPLS 200 HV3

19 g

11 g

CPLS 250 Std, HV1

65 g

50 g

CPLS 250 HV2

55 g

40 g

Specific greasing information for CPLS 160 HV3 and

200 HV3 (high-speed) motors

After 5 greasings, the DE and NDE grease traps must be

dismantled, emptied and cleaned.

(See the “Cleaning the grease traps” section).

After regreasing, do not start the motor

immediately at very high speed.

Proceed in stages:

- Run the motor up to 3000 min

-1

and wait for the bearing

temperature to stabilise (10-15 min approximately).

- Increase the motor speed by another 3000 min

-1

and

wait for the bearing temperature to re-stabilise (another

10-15 minutes approximately).

The motor can then be used normally

As a rule, abrupt, frequent changes of motor speed

should be avoided, so as to “smooth out” temperature

variations in the end shields as much as possible. The

grease will then work optimally, and the bearing and

grease life will be maximised.

Cleaning the grease traps

On the DE shield:

- Take off the coupling and the shaft extension key.

- Undo the CHC screws holding the trap, and release it.

- Empty out the waste grease, clean the trap, and the grease

valve.

- Refit the trap, the CHC screws, the shaft extension key and

the coupling.

On the NDE shield:

- Remove the 3 CHC screws from the encoder protective

cover, the encoder support is also released.

- Loosen the encoder driving ring screw (at the encoder

drive end).

- Remove the encoder from the motor shaft with its support.

- Undo the CHC screws holding the trap, and release it.

- Empty out the waste grease, clean the trap, and the grease

valve.

- Refit the trap and CHC screws.

- Refit the encoder on the shaft, with its support.

- Tighten the encoder driving ring screw.

- Refit the encoder protective cover and the 3 CHC screws.

When tightening its screws, be sure not to force the encoder

feet: it must remain centred on the shaft. Forcing it could cause

high-speed vibrations, with damaging effects on the encoder .

Summary of Contents for CPLS 112

Page 27: ......