Maintenance/repair

Temperature monitoring

7

l

28

BA 13.0008 − EN 2.1

7

Maintenance/repair

{

Danger!

ƒ

Ensure that no voltage is applied to the drive system while working on it!

ƒ

High temperatures of the motor surfaces. Observe cooling times!

ƒ

Unload motor or secure loads which are applied to the drive!

ƒ

Ensure that no foreign particles ingress into the motor!

7.1

Temperature monitoring

If the surface temperatures are higher than usual, it might be necessary to check the

actual winding temperature:

ƒ

Detect the winding temperature by means of a 4−conductor resistance

measurement at the motor power connections.

ƒ

The resistance should be measured immediately after switch−off and standstill of

the motor.

Procedure

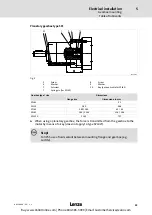

1. Remove the plug−in connector X10. For terminal box designs, interrupt the power

supply between inverter and motor.

2. Measure the resistance between the following contacts or terminals:

– Plug−in connector X10:

Contacts 4

«

5, 5

«

6 and 6

«

4

– Terminal box X11:

Terminals 1

«

2, 2

«

3 and 3

«

1

3. The mean value calculated from three measuring values equals the double phase

resistance (star connection).

– Enter the mean value as "R

2

" in the following formula and calculate the winding

temperature "

J

2

" ( "R

1

" from Tab. 3):

í

2

[°C]

+

R

2

y

255

R

1

y

235

Motor type

Winding resistance

D

230V

Y 390V

SDSG

LLL

047

28.7

86

SDSG

LLL

056

13.1

39.6

SDSG

LLL

063−22

6.7

20

SDSG

LLL

063−32

3.8

11.4

Tab. 3

Winding resistances of servo motors (between two terminals)

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]