Technical data

Rated data

3

l

13

BA 13.0008 − EN 2.1

3

Technical data

3.1

Rated data

ƒ

The most important rated data of the motor are indicated on the nameplate.

– Further technical data can be obtained from the catalogs.

ƒ

The torques and weights indicated in Tab. 2 are guide values for the selection of the

transmission elements and base.

ƒ

The rated data indicated on the nameplate refer to operation with Lenze servo

inverters of the 9300 series with an inverter input voltage (mains voltage) of 400 V

and an inverter frequency of 8 kHz.

)

Note!

ƒ

The motors can also be connected to inverters others than inverters of the

9300 series:

– Observe the minimum frequencies (Tab. 1).

– Depending on the modulation and control performance of the inverter it

might be necessary to derate the power if excessive temperatures are

detected (see chap. 3.2.1).

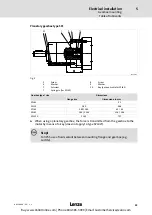

Motor type

Min. cycle frequency

[kHz]

SD

LL

A 047...063

8

Tab. 1

Minimum permissible inverter cycle frequencies

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]