Installation

3.2.2

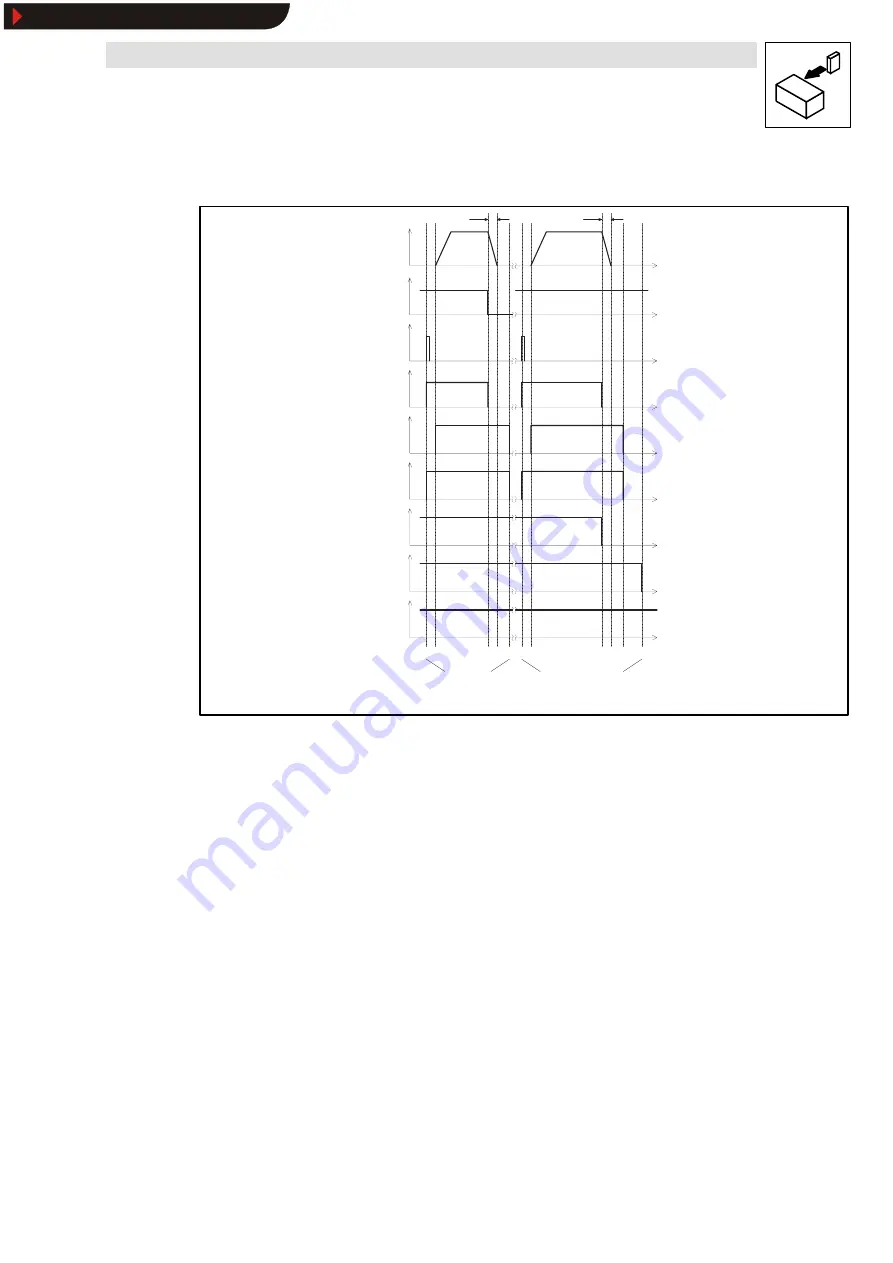

Time chart

n

Q S P

R F R

K

S R

t

Q S P

t 1

t 2

t 3 t 4

t 5

t

A 2

K 4

S 4

t

t

t

t

tt

tt

tt

tt

t 1

t 2

t 3

t 4

t 5

t 6

t

Q S P

" S a f e s t a n d s t i l l "

f u n c t i o n v i a

s t a r t - s t o p m o m e n t a r y

c o n t a c t p u s h b u t t o n

" S a f e s t a n d s t i l l "

f u n c t i o n v i a

" O p e n i n g o f s a f e t y d o o r "

S 2

tt

S 1

tt

Fig. 4

Time characteristic for switching on and off

“

safety relay and standard PLC control

”

3.2.3

Time settings

•

t1 to t2

≥

50 ms

Set the time delay in the PLC so that the controller will be enabled at least 50 ms after K

SR

.

•

t3 to t4

t

QSP

= Time for controller-internal QSP ramp

The time interval set must ensure that the controller can always be braked to a controlled

standstill when running at max. speed (t3 to t4).

•

t3 to t5 = t

QSP

+ min. 100 ms (standard value)

Set the time (t3 to t5) so that t

QSP

+ min. 100 ms ensures safety.

This ensures a controlled standstill according to stop catergory 1 of EN 60204-1. The

controller will only be enabled again (terminal 28) (t5) once the motor as been braked to a

controlled standstill (t4).

•

t3 to t6 = Internal time of A1, A2 (t

A1

, t

A2

)

t

A1

and t

A2

must be selected to ensure that the controller brakes the motor to a controlled

standstill along the QSP ramp within T

QSP

before the power supply is disconnected via the

mains contactor (K4) (t6). This will be required if

–

the emergency off button (S3) is pressed during operation.

–

the safety door is opened and the feedback contact of K

SR

in the controller is not closed

because of an error in the drive (t6) (2nd switch-off circuit).

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: [email protected]

Show/Hide Bookmarks