506305-01

Page 7 of 36

Issue 0938

Preferred fittings are DWV style or long sweep. Seal all joints

gas tight with appropriate cement. In areas where vent and

air intake pipes are exposed to abnormal stress or are subject

to damage, schedule 80 pipe should be used.

Category IV Furnace Limitations

This furnace shall

not

be connected to any Type B, BW, or L

vent or vent connector and shall

not

be connected to any portion

of a factory-built or masonry chimney.

This furnace is not to

be common vented with any other appliance. The vent

pipe must not be connected to a chimney flue serving a

separate appliance designed to burn solid fuel.

Concentric Vent Kit

cement. The cement shall show no gelation, stratification,

or separation that cannot be removed by stirring.

Refer to Table 2 for approved piping and fitting materials.

Canadian Applications Only:

PVC pipe, fittings, primer

and solvent cement used to vent this applicance must be

certified to ULC S636 and supplied by a single manufacturer

as part of an approved venting system. In addition, the first

three feet of vent pipe from the furnace flue collar must be

accessible for inspection. Models that may be installed as a

horizontal furnace include a horizontal drain kit. In Canada

this drain kit must be replaced by a locally available IPEX

Drain Kit # 196014.

For Local IPEX Canadian Customer

Service Center and Kit abailability call IPEX at 1-866-473-

9462.

The primers and solvents used must also meet ASTM

specifications. PVC primer is specified in ASTM F656. Use

PVC solvent as specified in ASTM D2564 and ABS solvent

cement as specified ASTM D2235. Low temperature solvent

cement is recommended. Metal or plastic strapping may

be used for vent pipe hangers.

When making ABS joints, pieces can be prepared with a clean

dry cloth to clean inside socket surface of fitting and male end

of pipe to depth of socket. Refer to procedure specified in

ASTM D3138. When joining ABS to PVC materials, use

transition solvent.

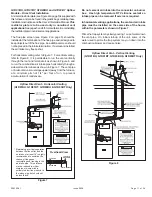

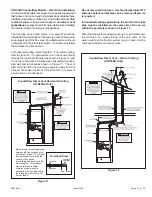

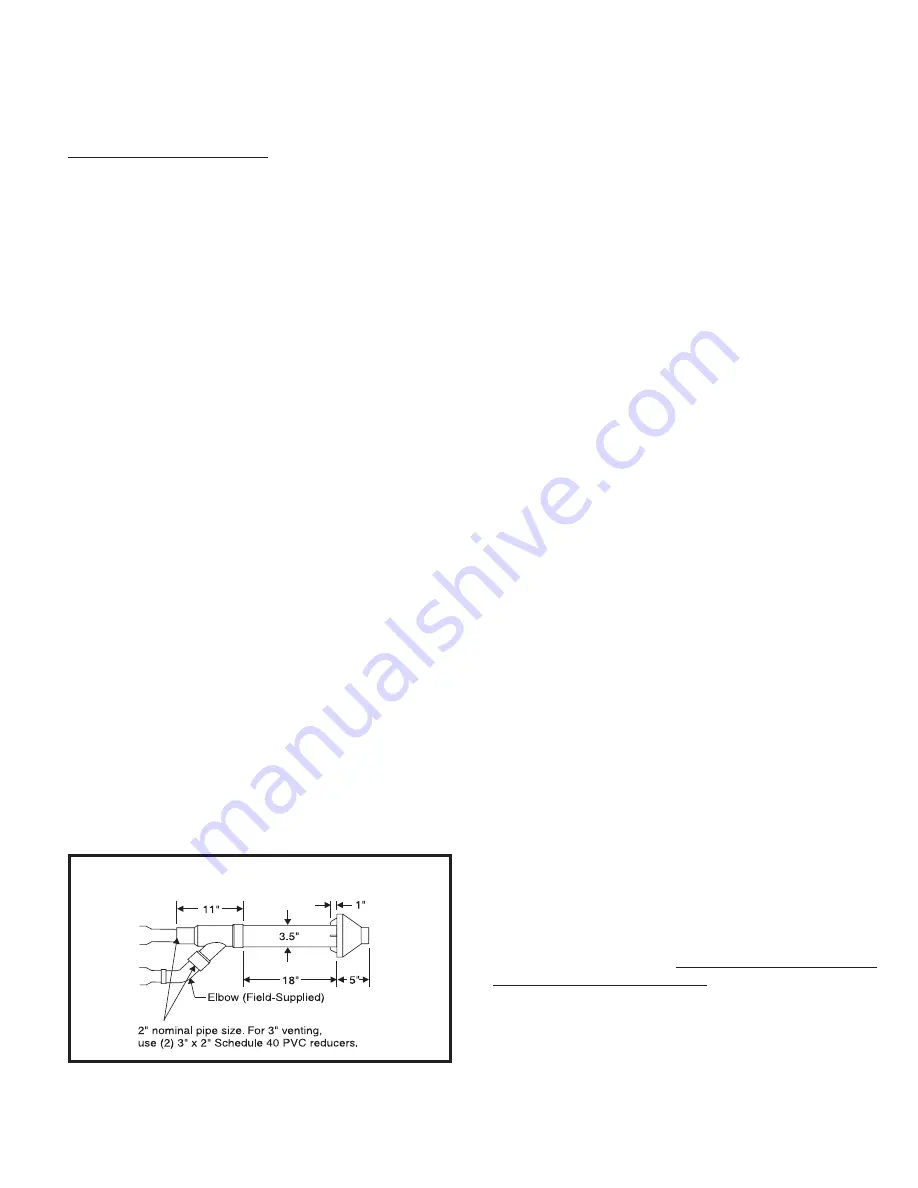

Figure 3

Concentric Vent Kit Dimensions

A concentric vent kit (see Accessories section on page 31 for

correct kit) is available for use when installing this furnace as

a direct vent furnace and the air intake and vent pipe are to be

run through the same hole, whether horizontally through the

wall or vertically through the roof (see Figure 3). Refer to the

instructions included with the concentric vent kit for installation

specifics.

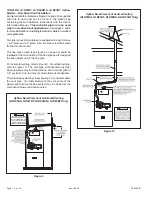

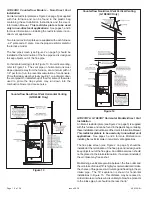

Vent Pipe Size and Length

The vent pipe and air intake pipe (in direct vent installations)

should be sized in accordance with the information found in

the appropriate table in Figure 4. One 90° elbow is equivalent

to 5' of pipe. Two 45° elbows are equivalent to one 90°

elbow. The minimum length certified for use with this furnace

is 5' and one elbow, not including the vent and air intake

terminals.

In the event that the pipe length is in between the lengths

listed in the table, use the next larger length listed. For

example, if a length of pipe needed to install the furnace is

27', use the diameter values for the 30' row in the tables.

For direct vent installations, if the vent and air intake pipe

are not equal in length and number of elbows, then determine

the minimum pipe diameter for both the vent and air intake.

If the results indicate different diameters, use the larger of

the two for both the vent and air intake.

Under no

circumstances should the vent and air intake pipe size

be different in diameter.

For installation details, refer to

the appropriate section in pages 11 – 17 for the unit model

and type of installation.

High Altitude Installation:

2” pipe not recommended at

altitude above 4,000 feet. 3” pipe required for altitude above

5,000 feet.

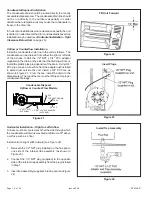

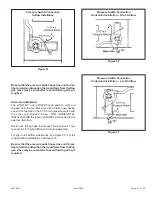

Horizontal Venting

The vent for this appliance shall not terminate over public

walkways; or near soffit vents or crawl space vents or other

areas where condensate or vapor could create a nuisance or

hazard or cause property damage; or where condensate vapor

could cause damage or could be detrimental to the operation

of regulators, relief valves, or other equipment.

See Figures 5 and 6 on pages 9 and 10 for additional

information on where the horizontal vent terminal can and

cannot terminate.

For Massachusetts Installations:

The installation must

comply with Massachusetts 248 CMR 5.08 Modifications to

sections of NFPA-54, Chapter10. (See pages 35 and 36 )