Page 30

3- Press the SET key again to access Stage 1

Differential. DIF1 will blink and the screen will display

the current setting (5°F). Use the UP/DOWN arrow

keys to change the temperature.

4- Press the SET key again to access Stage 1 Heating

/ Cooling mode. H1 should be displayed. If C1 is

displayed, press the UP/DOWN arrow keys to

change the setting to H1.

5- Press the SET key again to access Stage 2

temperature. S2 will blink and display the current

temperature setting (42°F). Use the UP/DOWN

arrows to change the temperature

6- Press the SET key again to access Stage 2

Differential. DIF2 will blink and the screen will display

the current setting (5°F). Use the UP/DOWN arrow

keys to change the temperature.

7- Press the SET key again to access Stage 2 Heating

/ Cooling mode. H2 should be displayed. If C2 is

displayed, press the UP/DOWN arrow keys to

change the setting to H2.

Water Quality Guidelines

Water Conditioning

The water-to-refrigerant coil requires varying degrees

of protection depending on water quality. Water quality

varies from location to location and is unique to each

site. Water typically contains impurities and hardness

that must be removed. The required treatment will

depend on the water quality as well as the system type.

If water impurities exceed the maximum allowable

levels shown in table 19, the potential for serious

corrosion or scaling exists.

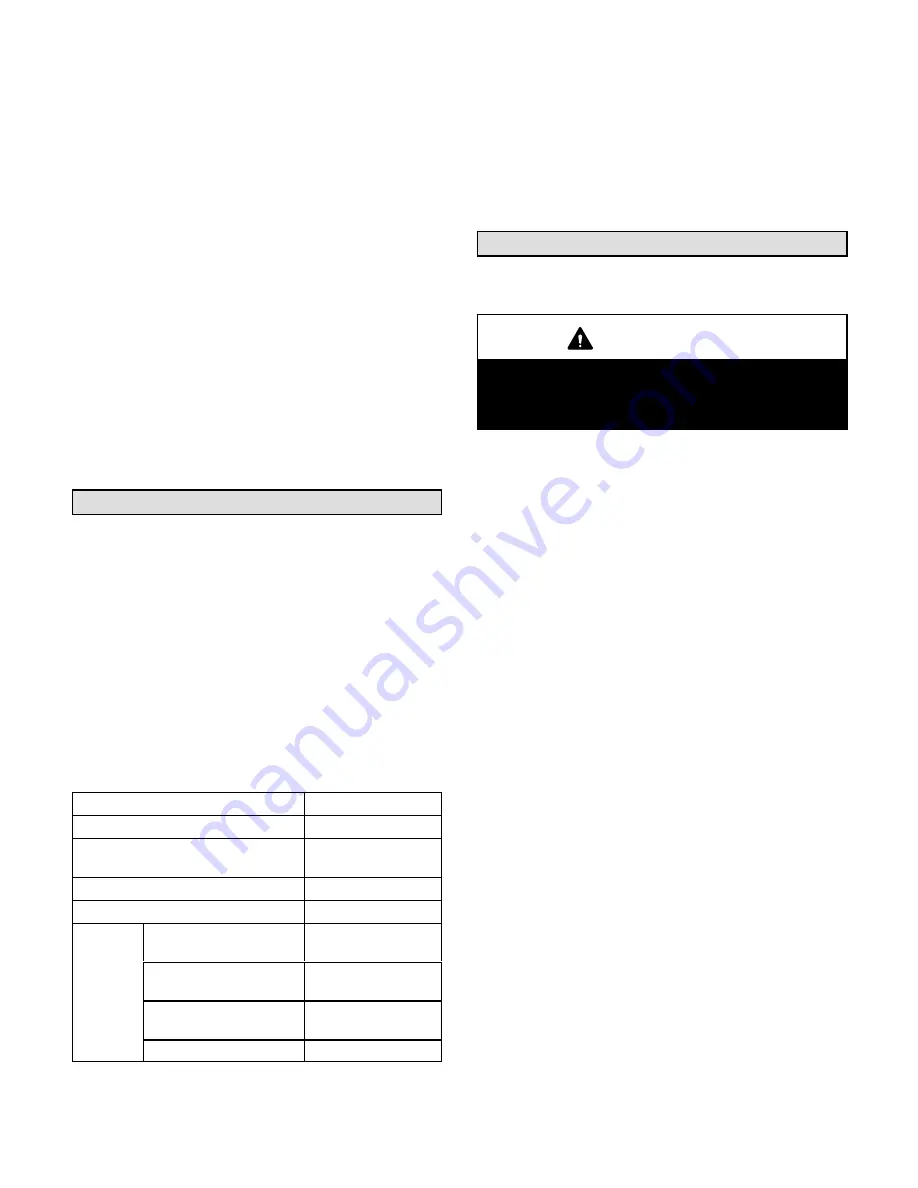

TABLE 19

ALLOWABLE WATER QUALITY LEVELS

Condition

Acceptable Level

pH

7 to 9.0

Total Hardness

(Calcium and Magnesium)

Should not exceed

350 ppm

Iron Oxides

Less than 1 ppm

Iron Bacteria

No level allowable

Corrosion

Ammonia, Ammonium

Hydroxide

0.5 ppm maximum

Ammonium chloride,

Ammonium

0.5 ppm maximum

Nitrate Ammonium

Sulfate

0.5 ppm maximum

Hydrogen Sulfide

No level allowable

Maintenance

Water quality should be checked periodically to maintain

acceptable water quality levels. If the water-to-refrigerant

coil becomes contaminated with dirt or scaling, the coil

will have to be back-flushed and cleaned with chemicals

that will remove the scale. This service should be

performed by an experienced water treatment specialist.

Service

The unit should be inspected once a year by a qualified

service technician.

CAUTION

Label all wires prior to disconnection when servic

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

A-Filters

Units are equipped with the following filters:

036/060 Units: Four 16 X 20 X 2” (406 X 508 X 51mm)

120 Units - Six 16 X 25 X 2” (406 X 635 X 51mm)

240 Units: Twelve 20 X 20 X 2” (508 X 508 X 51mm)

Filters should be checked monthly and replaced when

necessary with filters of like kind and size. Take note of

air flow direction marking on filter frame when

reinstalling filters. See figure 32.

NOTE-Filters must be U.L.C. certified or equivalent for

use in Canada.

Check and replace or clean economizer filters as needed.

B-Lubrication

All motors are lubricated at the factory. No further

lubrication is required.

C-Evaporator Coil

Inspect and clean coil at beginning of each cooling

season. Clean using mild detergent or commercial coil

cleaner. Flush coil and condensate drain with water

taking care not to get insulation, filters and return air

ducts wet.

D-Supply Air Blower Wheel

Annually inspect supply air blower wheel for accumulated

dirt or dust. Turn off power before attempting to remove

access panel or to clean blower wheel.