Page 38

IV-HEATING SYSTEM SERVICE CHECKS

A-CSA Certification

All units are CSA design certified without modifications.

Refer to the SL280DFV Installation Instruction.

B-Gas Piping

IMPORTANT

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outside

the furnace cabinet. The flexible connector can then

be added between the black iron pipe and the gas

supply line.

WARNING

Do not over torque (800 in-lbs) or under torque (350

in-lbs) when attaching the gas piping to the gas

valve.

Gas supply piping should not allow more than 0.5”W.C.

drop in pressure between gas meter and unit. Supply gas

pipe must not be smaller than unit gas connection.

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gases.

C-Testing Gas Piping

IMPORTANT

In case emergency shutdown is required, turn off the

main shut-off valve and disconnect the main power

to unit. These controls should be properly labeled

by the installer.

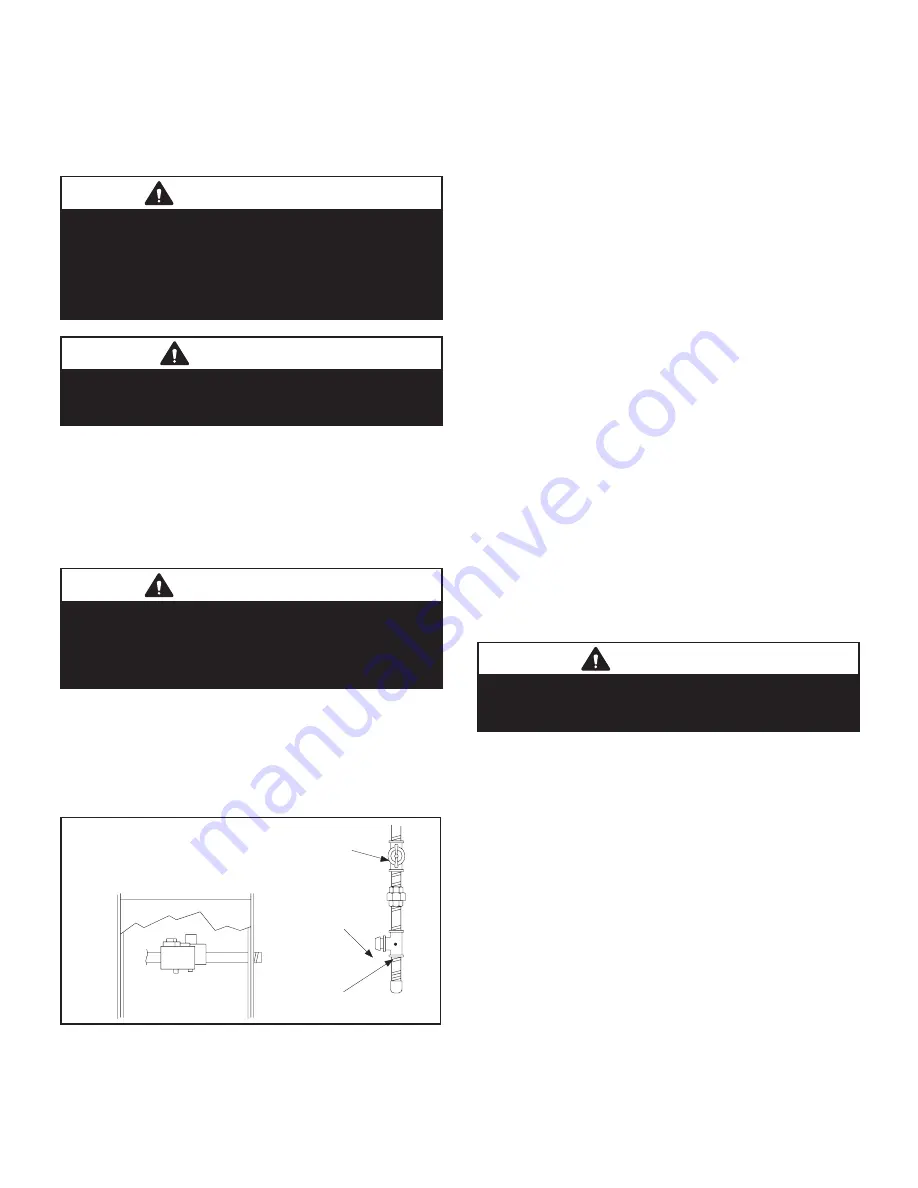

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged

if subjected to more than 0.5 psig (14” W.C.). See FIG-

URE 19. If the pressure is equal to or less than 0.5psig

(14”W.C.), use the manual shut-off valve before pressure

testing to isolate furnace from gas supply.

MANUAL MAIN SHUT-OFF VALVE

WILL NOT HOLD TEST PRESSURE

IN EXCESS OF 0.5 PSIG (14”W.C.)

GAS VALVE

CAP

GAS PIPING TEST PROCEDURE

FIELD PROVIDED

LINE PRESSURE TAP

FIGURE 19

When checking piping connections for gas leaks, use

preferred means. Kitchen detergents can cause harmful

corrosion on various metals used in gas piping. Use of a

specialty Gas Leak Detector is strongly recommended. It

is available through Lennox under part number 31B2001.

See Corp. 8411-L10, for further details.

Do not use matches, candles, flame or any other source of

ignition to check for gas leaks.

D-Testing Gas Supply Pressure

White Rodgers Gas Valve

An inlet post located on the gas valve provides access to

the supply pressure. See FIGURE 17. Back out the 3/32

hex screw one turn, connect a piece of 5/16 tubing and

connect to a manometer to measure supply pressure. See

TABLE 20 for supply line pressure.

Honeywell / ResideoGas Valve

A threaded plug on the inlet side of the gas valve provides

access to the supply pressure tap. Remove the threaded

plug, install a field-provided barbed fitting and connect a

manometer to measure supply pressure. See TABLE 20

for supply line pressure. Replace the threaded plug after

measurements have been taken.

E-Check Manifold Pressure

After line pressure has been checked and adjusted, check

manifold pressure. Move pressure gauge to outlet pres-

sure tap located on unit gas valve (GV1). Checks of man-

ifold pressure are made as verification of proper regulator

adjustment.

Manifold pressure can be measured at any time the gas

valve is open and is supplying gas to the unit. See TABLE

20 for normal operating manifold pressure.

CAUTION

For safety, connect a shut\-off valve between the

manometer and the gas tap to permit shut off of gas

pressure to the manometer.

The gas valve is factory set and should not require adjust-

ment. All gas valves are factory regulated.

Manifold Adjustment Procedure:

1 - Connect test gauge to manifold pressure post

(FIGURE 17) or tap (FIGURE 18) on gas valve.

2 - Ignite unit on low fire and let run for 5 minutes to

allow for steady state conditions.

3 - After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

4 - If necessary, make adjustments. FIGURE 17 and

FIGURE 18 show location of high fire and low fire

adjustment screw.

5 - Repeat steps 2, 3 and 4 on high fire.

6 - Shut unit off and remove manometer as soon as an

accurate reading has been obtained. Take care to

replace pressure tap plug.

7 - Start unit and perform leak check. Seal leaks if

found.