Page 9

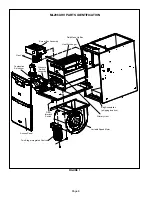

I-UNIT COMPONENTS

ML296UHV(X) unit components are shown in figure 1. The

gas valve, combustion air inducer and burners can be ac

cessed by removing the access panel. Electrical compo

nents are in the control box (figure 2) found in the blower

section.

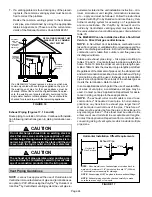

CAUTION

Electrostatic discharge can affect elec

tronic components. Take precautions

to neutralize electrostatic charge by

touching your hand and tools to metal

prior to handling the control.

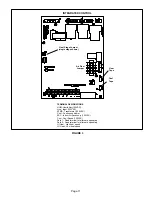

A- Control Box

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. Transformers on all

models are rated 40VA with a 120V primary and a 24V sec

ondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VAC is wired in se

ries with line voltage. When the inner blower access panel

is removed the unit will shut down.

FIGURE 2

Control Box Components

Integrated Control

Door Interlock Switch

Transformer

WARNING

Shock hazard.

Disconnect power before servicing. Integrated

control is not field repairable. If control is inoper

able, simply replace entire control.

Can cause injury or death. Unsafe operation will re

sult if repair is attempted.

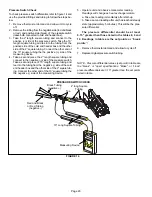

3. Integrated Control (A92)

Units are equipped with a two-stage, variable speed inte

grated control. The system consists of a ignition / blower

control (figure 3) with control pin designations in tables 3

and 4 and ignitor. The control and ignitor work in combina

tion to ensure furnace ignition and ignitor durability. The

control provides gas ignition, safety checks and indoor

blower control with two-stage gas heating. The furnace

combustion air inducer, gas valve and indoor blower are

controlled in response to various system inputs such as

thermostat signal, pressure and limit switch signal and

flame signal.

The furnace has a built-in, self-diagnostic capability. If a

system problem occurs, a fault code is shown by a

red

LED

on the control. The control continuously monitors its own

operation and the operation of the system. If a failure oc

curs, the LED will indicate the failure code. The flash codes

are presented in table 2.

Fault Code History Button

The control stores the last five fault codes in memory. A

pushbutton switch is located on the control. When the

pushbutton switch is pressed and released, the control

flashes the stored fault codes. The most recent fault code is

flashed first; the oldest fault code is flashed last. To clear

the fault code history, press and hold the pushbutton switch

in for more than 5 seconds before releasing.

Single Stage Thermostat Operation

The automatic heat staging option allows a single stage

thermostat to be used with two stage furnace models. To

activate this option, move the jumper pin (see Figure 3) to

desired setting (5 minutes or 10 minutes). The furnace will

start on 1st stage heat and stay at 1st stage heat for the

duration of the selected time before switching to 2nd stage

heat.

W1 on the integrated control must be connected to W1 on

the thermostat.

High Heat State LED

A

green

LED is provided on the control board to indicate

high heat state

(see Table 1).

CFM LED

An amber LED is provided on the control board to display

CFM. To determine what CFM the motor is delivering at any

time, count the number of times the amber LED flashes.

Each flash signifies 100 CFM; count the flashes and multi

ply by 100 to determine the actual CFM delivered (for ex

ample: 5 flashes x 100 = 500 CFM).