Page 24

IMPORTANT

If a highefficiency filter is being installed as part

of this system to ensure better indoor air quality,

the filter must be properly sized. Highefficiency

filters have a higher static pressure drop than

standardefficiency glass/foam filters. If the pressure

drop is too great, system capacity and performance

may be reduced.

The pressure drop may also cause the limit to trip

more frequently during the winter and the indoor

coil to freeze in the summer, resulting in an increase

in the number of service calls.

Before using any filter with this system, check the

specifications provided by the filter manufacturer

against the data given in the appropriate Lennox

Product

Specifications

bulletin.

Additional

information is provided in Service and Application

Note ACC002 (August 2000).

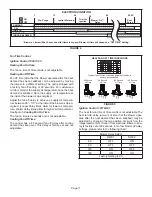

TABLE 15

Furnace Cabinet Width

Filter Size (inches)

A - 14-1/2”

14 X 25 X 1 (1)

B - 17-1/2”

16 X 25 X 1 (1)

C - 21”

20 x 25 x 1 (1)

5 - Check the condition and cleanliness of burners and

heat exchanger and clean if necessary.

6 - Check the cleanliness of blower assembly and

clean the housing, blower wheel and blower motor

if necessary. The blower motors are prelubricated

for extended bearing life. No further lubrication is

needed.

7 - Inspect the combustion air inducer and clean if

necessary.

8 -

Evaluate the heat exchanger integrity by inspecting

the heat exchanger per the AHRI heat exchanger

inspection procedure. This procedure can be

viewed at www.ahrinet.org

9 - Ensure sufficient combustion air is available to the

furnace. Fresh air grilles and louvers (on the unit

and in the room where the furnace is installed)

must be properly sized, open and unobstructed to

provide combustion air.

10 -

Inspect the furnace venting system to make sure

it is in place, structurally sound, and without holes,

corrosion, or blockage. Vent system must be free

and clear of obstructions and must slope upward

away from the furnace . Vent system should be

installed per the National Fuel Gas Code

11 -

Inspect the furnace return air duct connection to

ensure the duct is sealed to the furnace. Check for

air leaks on supply and return ducts and seal where

necessary.

12 - Check the condition of the furnace cabinet insulation

and repair if necessary.

13 - Perform a complete combustion analysis during the

furnace inspection to ensure proper combustion

and operation. Consult Service Literature for proper

combustion values.

14 - Verify operation of CO detectors and replace

batteries as required.

Perform a general system test. Turn on the furnace to

check operating functions such as the start-up and shut-

off operation.

1 -

Check the operation of the ignition system, inspect

and clean flame sensor. Check microamps before

and after. Check controls and safety devices (gas

valve, flame sensor, temperature limits). Consult

Service Manual for proper operating range. Thermal

Limits should be checked by restricting airflow and

not disconnecting the indoor blower. For additional

details, please see Service and Application Note

H049.

2 - Verify that system total static pressure and airflow

settings are within specific operating parameters.

3 - Clock gas meter to ensure that the unit is operating

at the specified firing rate. Check the supply

pressure and the manifold pressure. On two-stage

gas furnaces check the manifold pressure on high

fire and low fire. If manifold pressure adjustment is

necessary, consult the Service Literature for unit

specific information on adjusting gas pressure.

Not all gas valves are adjustable. Verify correct

temperature rise.