Page 6

I-UNIT COMPONENTS

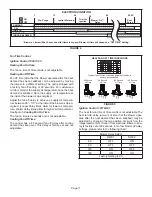

Unit components are shown in figure 1.The gas valve,

combustion air inducer and burners can be accessed by

removing the upper access panel. Electrical components

are in the control box (figure 2) found in the blower section.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect

electronic components. Take precautions

to neutralize electrostatic charge by

touching your hand and tools to metal

prior to handling the control.

1. Control Transformer (T1)

A transformer located in the control box provides power to

the low voltage section of the unit. Transformers on all

models are rated 40VA with a 120V primary and a 24V

secondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VAC is wired in

series with line voltage. When the blower door is removed

the unit will shut down.

NOTE -

The door interlock switch is a safety switch. Do

not by-pass or jumper switch.

CONTROL BOX

DOOR INTERLOCK

SWITCH (S51)

INTEGRATED CONTROL

(A92)

TRANSFORMER

(T1)

CIRCUIT

BREAKER

(CB8)

FIGURE 2

3. Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box. The

switch provides overcurrent protection to the transform

-

er (T1). The breaker is rated at 3A at 32V. If the current

exceeds this limit the breaker will trip and all unit opera

-

tion will shutdown. The breaker can be manually reset by

pressing the button on the face.

4. Integrated Control (A92)

103217-03 & 107163-01

WARNING

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply

replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

The hot surface ignition control system consisting of an

integrated control (figure 3 with control terminal designa

-

tions in tables 1, 2 and 3), sensor and ignitor (figure 6).

The integrated control and ignitor work in combination to

ensure furnace ignition and ignitor durability. The integrat

-

ed control, controls all major furnace operations. The inte

-

grated control also features a RED LED for troubleshoot

-

ing and two accessory terminals rated at (1) one amp. The

nitride ignitor is made from a non-porous, high strength

proprietary ceramic material that provides long life and

trouble free maintenance.

Electronic Ignition (Figure 4)

On a call for heat the integrated control monitors the com

-

bustion air inducer pressure switch. The control will not

begin the heating cycle if the pressure switch is closed

(bypassed). Once the pressure switch is determined to

be open, the combustion air inducer is energized. When

the differential in the pressure switch is great enough, the

pressure switch closes and a 15-second pre-purge be

-

gins. If the pressure switch is not proven within 2-1/2 min

-

utes, the integrated control goes into Watchguard-Pres

-

sure Switch mode for a 5-minute re-set period.

After the 15-second pre-purge period, the ignitor warms

up for 20 seconds during which the gas valve opens at

19 seconds for a 4-second trial for ignition. The ignitor re

-

mains energized for the first 3 seconds during the 4 second

trial. If ignition is not proved during the 4-second period,

the integrated control will try four more times with an inter

purge and warm-up time between trials of 35 seconds.

After a total of five trials for ignition (including the initial

trial), the integrated control goes into Watchguard-Flame

Failure mode. After a 60-minute reset period, the integrat

-

ed control will begin the ignition sequence again.