Page 22

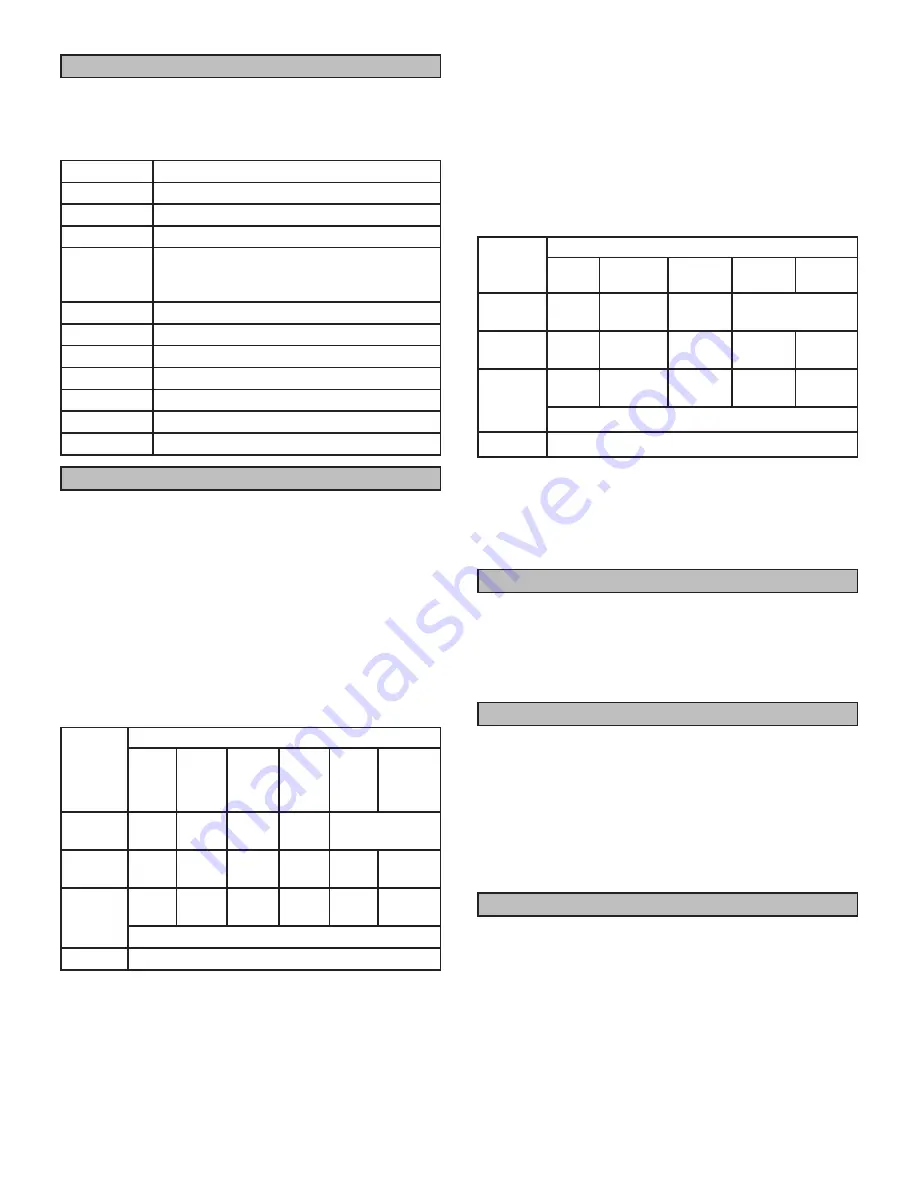

Ignition Control LED

The ignition control contains a green LED which indicates

the following:

TABLE 6

IGNITION CONTROL LED

LED

UNIT OPERATION

Slow Flash*

Normal Operation - No call for heat

Fast F;lash

Normal Operation - Call for heat

2 Flashes

System lockout - failed to detect or sustain flame

3 Flashes

Pressure switch failed closed before CAI

is energized or failed open after CAI is

energized

4 Flashes

High limit (S10) switch open

5 Flashes

Flame sensed and gas valve (GV1) not energized

6 Flashes

On-board microprocessor fault.

7 Flashes

Pressure switch (S18) closed with inducer off.

8 Flashes

Rollout switch (S47/S195) open. Cycle-power to reset.

Steady On

Control board (A3) failure

Steady Off

Internal control board (A3) failure or not power.

High Altitude Adjustments

In Canada, certification for installation at altitudes over

4500 feet (1372m) above sea level is the jurisdiction of

local authorities. Lennox recommends derating 4%/1000

feet above 4,500 feet. Refer to table 7 for natural gas

manifold pressures and the Engineering Handbook for

high altitude kit part numbers.

Units may be fired at full input up to 2000 feet. (610m)

above sea level. Above 2000 feet (610m), manifold pres-

sure must be adjusted. Adjust pressure regulator to pres-

sure shown in table 7.

TABLE 7

CANADA - NATURAL GAS MANIFOLD PRESSURES

[inch w.g. (kPa)]

Unit

Altitude in Feet (Meters)

0-2000

(0- 610)

2001-

4500

(610-

1372)

4501-

5500

(1372-

1676)

5501-

6500

(1677-

2012)

6501-

7500

(2012-

2286)

7501-

9500

(2286-

2896)

125, 150,

175, 200

3.5

(0.87)

3.1

(0.77)

2.8

(0.70)

2.6

(0.65)

See Kit Instruction

250, 300,

350, 400

3.7

(0.92)

3.2

(0.80)

2.9

(0.72)

2.8

(0.70)

2.6

(0.65)

See Kit

Instruction

250, 300,

350

3.7*

(0.92)

3.3*

(0.82)

2.9*

(0.72)

2.8*

(0.70)

2.6*

(0.65)

See Kit

Instruction

1.6** (0.40)

400

1.7**(0.42)

* High Fire **Low Fire

NOTE -

A natural to LP/propane gas changeover kit is

required to convert the unit in the field. Refer to the in

-

stallation instructions supplied with the changeover kit for

conversion procedure.

In the US, units may be fired at full input up to 2000 feet

(610m) above sea level. Above 2000 feet (610m), unit

must be de-rated by four percent per 1000 feet for in-

stallation above 2000 feet. The de-rate may be accom-

plished by adjusting the manifold pressure. Refer to table

8 for natural gas manifold pressures and the Engineering

Handbook for high altitude kit part numbers.

TABLE 8

US - NATURAL GAS MANIFOLD PRESSURES

[inch w.g. (kPa)]

Unit

Altitude in Feet (Meters)

0-2000

(0- 610)

2001-3000

(610- 914)

3001-4000

(915- 1219

4001-5000

(1220-1524)

5001-10000

(1524-3048)

125, 150,

175, 200

3.5

(0.87)

2.9

(0.72)

2.7

(0.67)

See Kit Instruction

250, 300,

350, 400

3.7

(0.92)

3.1

(0.77)

2.8

(0.70)

2.6

(0.65)

See Kit

Instruction

250, 300,

350

3.7*

(0.92)

3.1*

(0.77)

2.8*

(0.70)

2.6*

(0.65)

See Kit

Instruction

1.6** (0.40)

400

1.7** (0.42)

* High Fire **Low Fire

In some cases, it is necessary to change the pressure

switch to ensure proper operation at higher altitudes. See

EHB for high altitude pressure switch kits.

The combustion air inducer proving switch is factory set.

No adjustment is necessary.

Gas Flow

To check for proper gas flow to the combustion chamber,

determine the Btu input from the appliance rating plate. Di-

vide this input rating by the Btu per cubic feet of available

gas. Result is the required number of cubic feet per hour.

Determine the flow of gas through the gas meter for two

minutes and multiply by 30 to get the hourly flow of gas.

Supply Gas Pressure Adjustment

Supply pressure should be checked with unit firing at max

-

imum rate. For Natural Gas, supply pressure should be

maintained in accordance with the specified minimum and

maximum supply pressures on the unit rating plate.

A natural gas to LP/propane gas changeover kit is re-

quired to convert the unit in the field. Refer to installation

instructions provided with changeover kit for conversion

procedure along with propane minimum and maximum

supply pressures.

Supply Pressure Measurement

1 -

Shut off the manual main supply valve (field

furnished) when installing or removing the measuring

device (Steps 2 and 6).

2 – Connect the measuring device based upon type of

gas valve.

For White Rodgers 36G valve (Figure 13), an inlet post lo-

cated on the gas valve provides access to the supply pres-

sure. Open the inlet port by backing out the 3/32” hex screw

one turn. Connect a piece of tubing over the inlet post and

route to a measuring device to measure supply pressure.

Summary of Contents for LS25 Series

Page 5: ...Page 5 ...