Page 9

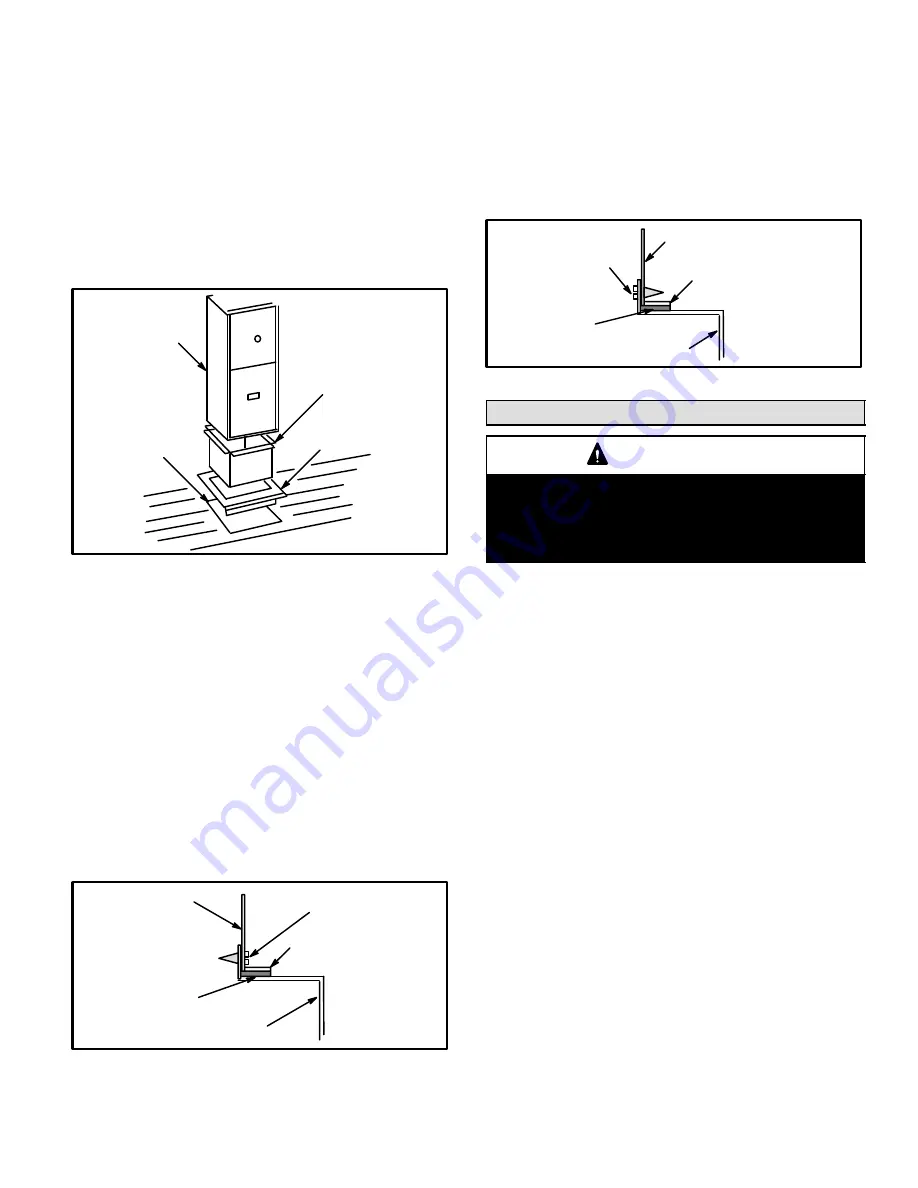

2 − After opening is cut, set additive base into opening.

3 − Check fiberglass strips on additive base to make sure

they are properly glued and positioned.

4 − Lower supply air plenum into additive base until ple-

num flanges seal against fiberglass strips.

NOTE − Be careful not to damage fiberglass strips.

Check for a tight seal.

5 − Set the furnace over the plenum.

6 − Ensure that the seal between the furnace and plenum

is adequate.

G40DF(X)UNIT

SUPPLY AIR PLENUM

ADDITIVE BASE

PROPERLY

SIZED FLOOR

OPENING

FIGURE 6

Installation on Cooling Cabinet

1 − Refer to reverse−flow coil installation instructions for

correctly sized opening in floor and installation of cabi-

net.

2 − When cooling cabinet is in place, set and secure the

furnace according to the instructions that are provided

with the cooling coil. Secure the furnace to the cabinet.

3 − Seal the cabinet and check for air leaks.

Return Air Opening −− Downflow Units

The following steps should be taken when installing ple-

num:

1 − Bottom edge of plenum should be flanged with a

hemmed edge (See figure 7).

2 − Fiberglass sealing strips should be used.

SECURE FROM

OUTSIDE CABINET

HEMMED EDGE

PLENUM

FIBERGLASS SEALING

STRIP

(Field Provided)

CABINET SIDE PANEL

Side View

FIGURE 7

3 − In all cases, plenum should be secured to top flanges

of furnace with sheet metal screws.

4 − In closet installations, it may be impossible to install

sheet metal screws from the outside. In this case,

make plenum with a removable front and install

screws from the inside (See figure 8).

5 − Make certain that an adequate seal is made.

SECURE FROM

INSIDE CABINET

HEMMED EDGE

FIBERGLASS

SEALING STRIP

(Field Provided)

CABINET SIDE

PANEL

PLENUM

Side View

FIGURE 8

Setting Equipment

WARNING

Do not install the furnace on its front or its back. Do

not connect the return air ducts to the back of the fur-

nace. Doing so will adversely affect the operation of

the safety control devices, which could result in per-

sonal injury or death.

Install the G40DF(X) gas furnace as shipped.

Do not

install the furnace horizontally.

Select a location that allows for the required clearances

that are listed on the unit nameplate. Also consider gas

supply connections, electrical supply, vent connection,

and installation and service clearances [24 inches (610

mm) at unit front].

The unit must be level.

NOTE − 1/3 hp blower motors are equipped with four flex-

ible mounting legs, and 1/2 hp blower motors are equipped

with three flexible legs and one rigid leg. The rigid leg is

equipped with a shipping bolt and a flat white plastic wash-

er (rather than the rubber mounting grommet used with a

flexible mounting leg).

The bolt and washer must be re-

moved before the furnace is placed into operation.

Af-

ter the bolt and washer have been removed, the rigid leg

will not touch the blower housing.

NOTE − G40DF−36C−110 units include a bracket which sta-

bilizes the blower motor during shipping. The bracket is se-

cured to the blower housing by two screws.

This bracket

must be removed prior to placing the unit into opera-

tion.

See figure 1.

Downflow Application

Allow for clearances to combustible materials as indi-

cated on the unit nameplate. Minimum clearances for

closet or alcove installations are shown in figure 9.