FIGURE 26

STATIC PRESSURE

TEST

MANOMETER

OIL UNIT

Page 19

B-Temperature Rise

Temperature rise for O24 and OF24 units depends on unit in

put, blower speed, blower horsepower and static pressure.

The blower speed must be set for unit operation within the

range of AIR TEMP. RISE

°

F" listed on the unit rating plate.

To Measure Temperature Rise:

1 - Place plenum thermometers in the supply and return air

plenums. Locate supply air thermometer in the first hori

zontal run of the plenum where it will not pick up radiant

heat from the heat exchanger.

2 - Set thermostat to highest setting.

3 - After plenum thermometers have reached their

highest and steadiest readings, subtract the two

readings. The difference should be in the range listed

on the unit rating plate. If the temperature is too low, de

crease blower speed. If temperature is too high increase

blower speed to reduce temperature. To change blower

speed see Blower Speed section.

C-Blower Speed

Blower speed is regulated by means of an adjustable motor

pulley. Open pulley to decrease speed and close pulley to

increase speed. Adjust belt tension as loose as possible

without allowing slippage.

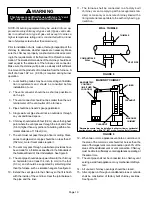

D-External Static Pressure

1 - Measure tap locations as shown in figure 26.

2 - Punch a 1/4" (6 mm) diame

ter hole in supply and return

air plenums. Insert manom

eter hose flush with inside

edge of hole or insulation.

Seal around the hose with

permagum. Connect the

zero end of the manometer

to the discharge (supply) side of the system. On

ducted systems, connect the other end of manometer

to the return duct as above. For systems with non-

ducted returns, leave the other end of the manometer

open to the atmosphere.

3 - With only the blower motor running and the evapora

tor coil dry, observe the manometer reading. Adjust

blower motor speed to deliver the air desired accord

ing to the job requirements.

4 - Pressure drop must not exceed 0.5" W.C. (124.3 Pa).

5 - Seal around the hole when the check is complete.

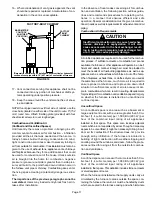

VII-MAINTENANCE

CAUTION

Never operate unit with access panels to the

blower compartment off or partially open.

A-Filters

If throwaway type filters are used, check monthly and re

place when necessary to assure proper furnace opera

tion. Replace filters with like kind and size.

If reusable type filters are used, check monthly and clean with

water and mild detergent when necessary. When dry, they

should be sprayed with filter handicoater prior to reinstallation.

Filter handicoater is RP Products coating no. 418 and is avail

able as Lennox part no. P85069.

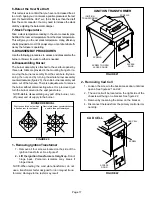

B-Cleaning Heat Exchanger

NOTE-Use papers or protective covering in front of fur

nace while cleaning furnace.

Cleaning the heat exchanger is made easier with a heat ex

changer cleanout kit ABRSH380 (catalog # 35K09) avail

able from Lennox.

Heat Exchanger

1 - Remove vent pipe from furnace.

2 - Remove locking screws and caps from cleanout tubes.

Remove vent access elbow.

3 - Using a long spiral wire brush, sweep down the outer

drum of the heat exchanger. Then using the hose at

tachment, vacuum out loose debris.

4 - Remove locking screw and cap from the observation tube

and with the spiral wire brush, reach upward toward

the rear of the heat exchanger to clean out the cross

over tube.

NOTE- Do not attempt to clean the combustion chamber.

It can be easily damaged.

5 - Replace the cleanout caps and vent access elbow.

Make sure locking screws are secure.

6 - Brush out and vacuum the vent outlet area of the outer

drum and replace vent pipe.

7 - Clean around the burner, blower deck and vestibule area.