Page 14

6 - After it has been determined that each appliance re

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and any

other fuel burning appliance to their previous condition of

use.

7 - If improper venting is observed during any of the

above tests, the common venting system must be

corrected.

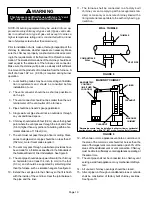

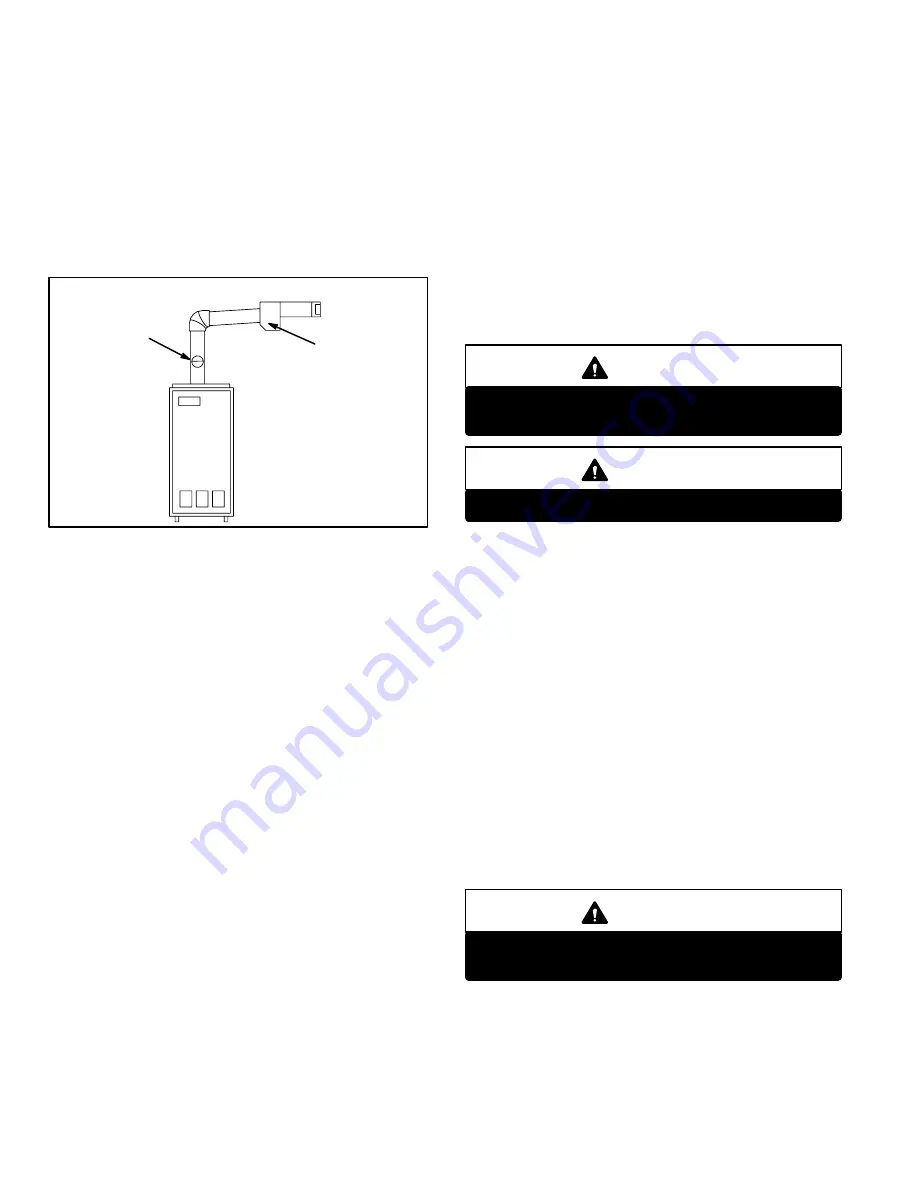

Horizontal Venting

HORIZONTAL VENTING

BAROMETRIC

CONTROL*

CONTROL FOR

HORIZONTAL

VENTING

FIGURE 15

*When using indoor air,

barometric control must be

installed in the horizontal

venting system and located

within 18" (457 mm) of vent

outlet of furnace.

When using direct connection,

barometric control must be

installed in the intake air pipe.

The O24 is approved for horizontal venting with the fol

lowing mechanical vent systems:

Tjernlund (sideshot) #SS1C and Field Controls #SWG-5 with

the CK-61 control kit. Refer to manufacturers' installation

instructions for proper installation procedures and service parts

information.

Do not common vent with any other appliance when using

sidewall vent system.

Maximum permissible vent length is 70 equivalent feet (21.3

m). Minimum length is 15 equivalent feet (4.6 m). Each 90

el

bow is equal to 6 feet (1.8 m) of straight pipe, each 45

elbow is

equal to 3 feet (0.9 m) of straight pipe. Minimum vent pipe di

ameter is 4" (102 mm) for the O24/OF24-70,-105/120 (R) and

5" (152 mm) for O24/OF24 (R)-140/154, however vent pipe of

5" (127 mm) and 6" (152 mm) is permissible. Calculate the

equivalent vent pipe footage from the furnace to the mechani

cal vent system (Tjernlund or Field Controls) by adding the

straight vent pipe length and the equivalent elbow lengths

together.

The barometric draft control must be used in horizontal (side

wall) venting system. It must be located within 18" (457 mm) of

the furnace vent outlet. See figure 15 for barometric draft con

trol location.

III-STARTUP

A-Preliminary and Seasonal Checks

1 - Inspect electrical wiring, both field and factory installed for

loose connections. Tighten as required.

2 - Check line voltage. Voltage must be within range

listed on the nameplate. If not, consult the power

company and have voltage condition corrected be

fore starting unit.

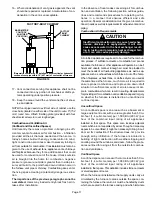

B-Bleeding Fuel Line

Before starting unit, make sure the oil tank is adequately

filled with clean No. 1 or No. 2 furnace oil.

NOTE - Water, rust or other contaminants in oil supply sys

tem will cause malfunction and failure of the internal parts of

the fuel unit.

CAUTION

Never burn garbage or paper in the heating sys

tem. Never leave papers near or around the unit.

CAUTION

Blower access door must be in place before start-up.

1 - Set thermostat for heating demand and turn on electri

cal supply to unit.

2 - Check initial air adjustment. All units are equipped with

an air adjustment dial on the right side of the burner.

See burner parts arrangement illustration.

3 - Turn unit on. Place a can or container under the bleed

port located on the fuel pump. Loosen nut on bleed port

to release air and oil mixture from fuel line. Allow mix

ture to escape until a steady stream of oil is emitted

from the port. Drain at least 1/2 pint of oil from the pump.

Retighten nut on bleed port. If unit locks out during

bleed procedure, push reset button on primary safety

control.

NOTE - A two

line fuel system will normally bleed itself

by forcing air back to the tank through the return line.

This type of bleeding procedure is not necessary.

4 - If burner fails to start, push reset button on primary

safety control. See part arrangement illustration.

CAUTION

Do not push the reset button on the primary con

trol more than one time.

5 - If burner fails to light again, refer to the troubleshooting

section in this manual.

6 - Proceed to section IV to complete start up.