# 45466K003

Page 20

OPERATION

Sequence of Operation

Heating

During a call for heat the thermostat closes the R-W

circuit of the control board. The control board verifies limit

switches are closed and pressure switch is open. The

induced draft blower relay closes causing the blower to

run. As vent pressure is developed by the induced draft

blower, the pressure switch closes. After a 15-second pre-

purge, the control energizes the hot surface ignitor. After

the 7-second warmup time, the control energizes the main

gas valve causing the main burners to ignite. The hot

surface ignitor is de-energized 3 seconds after the main

valve opens. If flame is sensed during this time the main

valve remains energized and the control starts the

30-second heat blower

“

on

”

delay.

As heating demand is met, the thermostat de-energizes the

R-W circuit. The control de-energizes the main valve

causing the burners to shut off. The induced draft blower

shuts off after a 15-second post-purge delay. The circulating

air blower will continue to operate until the user-selectable

heat blower

“

off

”

delay expires. The control return to standby

mode once the heat blower

“

off

”

delay expires.

Fan “On”

During a fan

“

on

”

call, the thermostat energizes the R-G

circuit of the control board, immediately causing the fan to

energize the COOL speed. The fan remains energized as

long as the thermostat calls for fan

“

on

”

operation.

If a call for cooling is energized during a fan

“

on

”

call, the fan

continues to operate at the COOL speed. If a call for heat is

energized during a fan

“

on

”

call, the control de-energizes the

fan immediately and begins the heat call/ignition sequence.

At the end of the fan

“

on

”

call the thermostat de-energizes

the R-G circuit of the control, causing the fan to be de-

energized immediately.

Cooling

During a call for cooling, the thermostat energizes the R-Y

circuit of the control board. After a 1-second cooling

“

on

”

delay, the control energizes the cooling fan speed. If the fan

is already energized, it remains running and does not de-

energize for the 1-second cooling fan

“

on

”

delay.

The call for cooling has priority over continuous fan

operation while a call for heating has priority over both a

call for cooling or continuous fan. Ignition lockouts for any

reason do not affect cooling operation.

As cooling demand is met, the thermostat de-energizes

the R-Y circuit of the control board. After a 60-second

cooling

“

off

”

delay, the control de-energizes the cooling

speed fan. At the end of the cooling

“

off

”

delay period, the

control returns to the standby mode.

Controls

Following is a description of the operation of some of the

controls used in this furnace. All models use one of each

control, except as noted.

Pressure Switch

The pressure switch is a normally open switch that

monitors combustion air flow. Inadequate air flow resulting

from excessive venting system restriction or a failed

combustion blower will cause the switch to remain open.

Rollout Switch

The rollout switch is a normally closed switch that opens

when abnormal temperatures exist in the burner area. This

can be caused by a restricted heat exchanger causing

main burner flame to

“

roll out

”

into the vestibule area or

burner box.

This switch must be manually reset by pushing the button

on top to restore furnace operation. G1D93BC units have

two rollout switches.

Primary Limit Control

This is a normally closed control that opens if abnormally

high circulating air temperatures occur. It is an automatic

reset control.

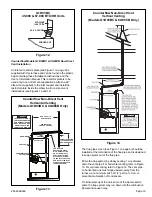

Auxiliary Limit Control

This is a normally closed control that opens under abnor-

mal

“

reverse air flow

”

conditions that could occur in a

counterflow or horizontal installation if the circulating

blower fails. It is an automatic reset control.

Upflow models do not include an auxiliary limit control.

Interlock (Blower Door) Switch

When the blower door is removed, the interlock switch

breaks the power supply to the burner controls and blower

motor. The switch operation must be checked to confirm it

is operating correctly.

Blower Control Board

The blower control board operates the circulating air

blower, the combustion blower and any accessories

connected to it. These models feature user-selectable

blower

“

off

”

delay times (60, 90, 120, and 180 seconds)

that are factory set to provide a 120-second blower

“

off

”

delay on heating (see wiring diagram on page 26).