Page 26

506727−01

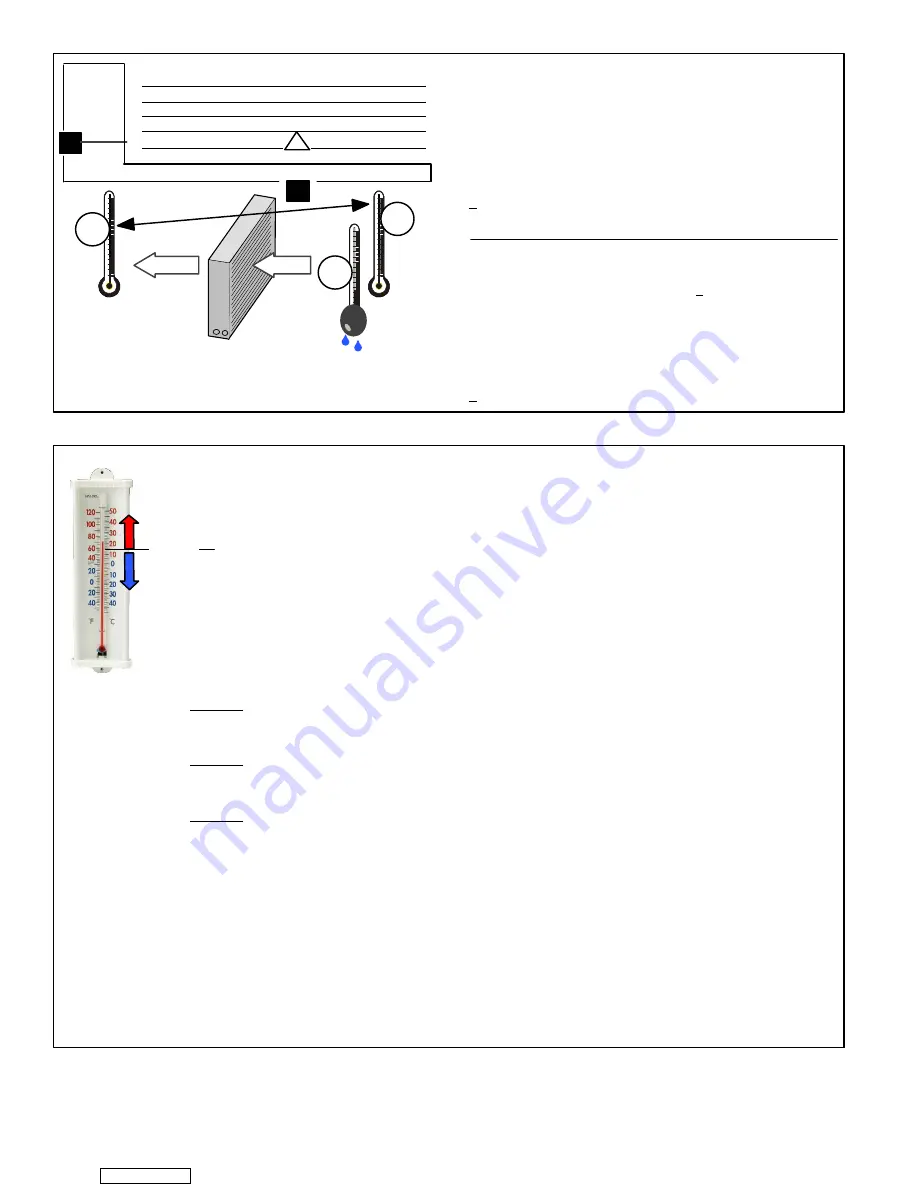

1. Determine the desired

D

T

Measure entering air temper-

ature using dry bulb (

A

) and wet bulb (

B

).

D

T

is the intersect-

ing value of

A

and

B

in the table (see triangle).

2. Find temperature drop across coil

Measure the coil’s dry

bulb entering and leaving air temperatures (

A

and

C

). Tem-

perature Drop Formula: (

T

Drop

) =

A

minus

C

.

3. Determine if fan needs adjustment

If the difference between

the measured

T

Drop

and the desired

D

T

(T

Drop

–

D

T)

is within

+3º, no adjustment is needed. See examples: Assume

D

T

=

15 and

A

temp. = 72º, these

C

temperatures would necessi-

tate stated actions:

Cº

T

Drop

–

D

T

=

ºF

ACTION

53º

19

–

15

=

4

Increase the airflow

58º

14

–

15

=

−1

(3º range) no change

62º

10

–

15

=

−5

Decrease the airflow

4. Adjust the fan speed

See indoor unit instructions to in-

crease/decrease fan speed.

Changing air flow affects all temperatures; recheck tempera-

tures to confirm that the temperature drop and

D

T are within

+3º.

D

T

80

24 24 24 23 23 22 22 22 20 19 18 17 16 15

78

23 23 23 22 22 21 21 20 19 18 17 16 15 14

76

22 22 22 21 21 20 19 19 18 17 16 15 14 13

74

21 21 21 20 19 19 18 17 16 16 15 14 13 12

72

20 20 19 18 17 17 16 15 15 14 13 12 11 10

70

19 19 18 18 17 17 16 15 15 14 13 12 11 10

57 58 59 60 61 62 63 64 65 66 67 68 69 70

Temp.

of air

entering

indoor

coil ºF

INDOOR

COIL

DRY

BULB

DRY

BULB

WET

BULB

B

T

Drop

19º

A

Dry−bulb

Wet−bulb ºF

A

72º

B

64º

C

53º

air flow

air flow

All temperatures are

expressed in ºF

Figure 22. Checking Airflow over Indoor Coil Using Delta−T Formula

1. Check liquid and vapor line pressures. Compare pressures with either second−stage heat or cooling mode

normal operating pressures listed in table 4. Table 4 is a general guide and expect minor pressures

variations. Significant pressure differences may indicate improper charge or other system problem.

2. Decide whether to use cooling or heating mode based on current outdoor ambient temperature:

A

Use

COOLING MODE

when:

Outdoor ambient temperature is

60°F (15.5°C) and above

.

Indoor return air temperature range is between

70 to 80°F (21−27°C)

. This temperature range is

what the target subcooling values are base upon in table 3.

If indoor return air temperature is not within reference range, set thermostat to cooling mode and a

setpoint of

68ºF (20ºC)

.

This should place the outdoor unit into second−stage (high−capacity)

cooling

mode. When operating and temperature pressures have stabilized, continue to step 3.

B

Use

HEATING MODE

when:

Outdoor ambient temperature is

59°F (15.0°C) and below

.

Indoor return air temperature range is between

65−75°F (18−24°C)

. This temperature range is

what the target subcooling values are base upon in table 3.

If indoor return air temperature is not within reference range, set thermostat to heating mode and a

setpoint of

77ºF (25ºC)

.

This should place the outdoor unit into second−stage (high−capacity)

heating

mode. When operating and temperature pressures have stabilized, continue to step 3.

it in the

SATº

space to the left.

4. Read the liquid line temperature; record in the

LIQº

space to the left.

5. Subtract

LIQº

temperature from

SATº

temperature to determine subcooling; record it in

SCº

space to the

left..

6. Compare

SCº

Heating

or

Cooling

mode column), also consider any additional

charge required for line set lengths longer than 15 feet and/or unit matched component combinations (

Add

Charge

column).

7. If subcooling value is:

AGREATER

than shown for the applicable unit match component,

REMOVE

refrigerant;

BLESS

than shown for the applicable unit match component,

ADD

refrigerant.

8. If refrigerant is added or removed, repeat steps 3 through 6 to verify charge.

9. Close all manifold gauge set valves and disconnect gauge set from outdoor unit.

10. Replace the stem and service port caps and tighten as specified in

Operating Service Valves

11. Recheck voltage while the unit is running. Power must be within range shown on the nameplate.

USE

COOLING

MODE

USE

HEATING

MODE

60ºF

(15ºC)

SATº

LIQº

–

SCº

=

Figure 23. Using HFC−410A Subcooling Method Second Stage (High Capacity) Optimizing Charge

Downloaded from