8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

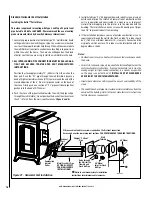

In addition to the standard installation instructions, the following instruc-

tions may be required by local, state or federal building codes:

• Installation should be in accordance with the Manufactured Home and

Safety Standard (HUD), CFR 3280, Part 24.

• The stove must be permanently bolted to the floor using 1/4" diameter

lag screws. The lag screws must be an adequate length to extend

through the hearth pad and into the floor as shown in

Figures 8 and 9

.

Install the lag screws as shown in these figures. Two lag screws must

be used.

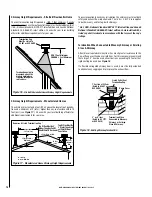

• Connecting the Bella™ stove to outside combustion air is required in

manufactured home installations and when required by local building

codes. An outside air inlet must be provided for combustion and be

unrestricted while unit is in use. Use a galvanized or stainless steel

pipe for the duct (the outside air inlet on the stove is 3” diameter).

The air intake on the exterior of the home should always be located

a minimum of 18" below the flue termination. The Inlet shall remain

free of obstruction while unit is in operation and constructed in a

manner so as to prevent material from dropping into the inlet or into

the area beneath the dwelling. The inlet shall also have a screen with

openings not larger than 1/4" to prevent rodents from entering. See

Figure 21.

• Stove must be permanently electrically grounded to the steel chassis

of the manufactured home using a 8 GA copper wire and a serrated

or star washer (to penetrate paint or protective coating to ensure

grounding). The location selected for ground attachment to the stove

must be dedicated for this purpose. Grounding must comply with

NFPA-70-latest edition standards, CSA C22.1-latest edition in Canada,

as well as any local codes.

• See

Pages 12 through 18

for additional information on venting require-

ments.

• WARNING: DO NOT INSTALL THIS STOVE IN A SLEEPING ROOM IN

A MANUFACTURED HOME.

• CAUTION: THE STRUCTURAL INTEGRITY OF THE MANUFACTURED

HOME FLOOR, WALLS, CEILING/ROOF MUST BE MAINTAINED.

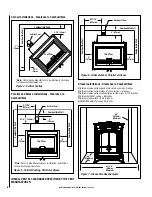

Figure 8 - Manufactured Home Installation

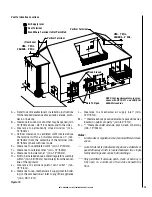

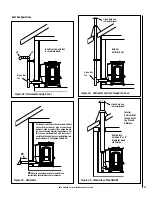

Manufactured Home Exhaust Vent Pipe Installation Guidelines

This stove is approved for venting with Type L and Type PL pellet vent pipe

listed to UL 641 and ULC S609. We recommend the use of venting prod-

ucts manufactured by Security Chimneys International. The pipe should

extend at least 3 feet above the part of the roof through which it passes.

The top of the pipe should be at least 2 feet above the highest required

elevation of any part of the manufactured home within 10 feet of the pipe

(see

Page 14

,

Manufactured Home Chimney Height Requirements

).

If the exhaust vent exits the manufactured home at a location other than

the roof, and exits at a point 7 feet or less above the ground level on which

the manufactured home is position a guard or method of enclosing the

pipe shall be provided at the point of exit for a height of up to 7 feet. The

openings, if any, in this guard shall not allow a 3/4” rod to pass through.

A 1/2” rod could pass through but should not be able to touch the pipe

when inserted through the opening a distance of 4 inches.

MANUFACTURED HOME INSTALLATION

Figure 9 - Manufactured Home Installation

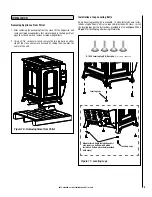

Attach the provided brackets to the stove using a 5/16" bolt. Install lag

screws through the holes in the bottom of the brackets to secure the legs

to the floor as shown here.

Bracket

Lag Screw

Chassis

Floor

Lag Screws

Floor

Protector

Summary of Contents for BELLA

Page 43: ...43 NOTES ...