OPERATING

Leister LHS SYSTEM

3

Installation

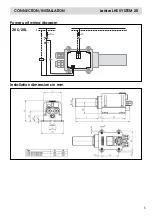

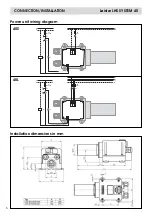

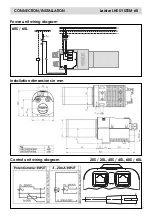

• When installing the tool, ensure that:

- only cold air is supplied

- no (hot air) back pressure develops

- the tool is not subjected to a hot air flow from another tool

• The tool is protected against mechanical vibration and shaking.

• Installation dimensions on pages 5, 6 and 7.

Air supply

• To protect the tool and the heat element, the stipulated minimum air flow must

under no circumstances fall short, and the maximum temperature (measured

at the hotest point 3 mm in front of the element housing) must also not be

exceeded. In the event that the minimum air flow falls short, the power must

immediately be disconnected.

• The air heater should only be supplied with air up to a max. 80°C.

• Pay attention to the direction of the airflow.

• Leister blowers must be used for the air supply (pay attention to the direction of

rotation and the electrical connection).

• For use in a dusty environment the tool should be fitted with a Leister stainless

steel filter on the air intake connection. Where a particularly critical dust problem

exists (eg metal, electrically charged or damp dust) special filters must be used to

avoid short circuiting of the tool.

Operation

• The tool must be connected by a qualified electrician in accordance with the

circuit diagram (Pages 5,6 or 7).

• Fit a nozzle appropriate to the use.

• It should be checked that the hot air can flow out freely, otherwise a back

pressure of hot air may damage the tool (danger of fire!).

• Attention: Keep to the minimum air flow according to the technical details

(Page 2).

• Switch on mains.

• Allow the tool to cool down after use.

Attention: Never operate tool without air supply!