OPERATION

SECTION 3

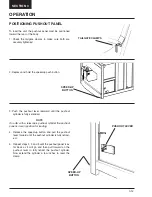

PUSHOUT PANEL OPERATION DURING PACKING

TELESCOPIC PUSH OUT

The 2RII Packmaster telescopic pushout cylinder will

normally move toward the front of the body automati-

cally. When the resistance circuit is adjusted to

produce maximum load density, it may become

necessary to manually retract the telescopic pushout

cylinder in order to allow the compacted refuse to

move forward in the body. Also, if the packer panel

stops short of the home position, the carrier panel

operating lever may need to be held (overridden) to

allow the refuse to move the pushout panel toward the

front of the body. When the pushout panel has reached

the front of the body, neither the packer panel operat-

ing lever nor the carrier panel lever should be overrid-

den except to clear the final hopper load.

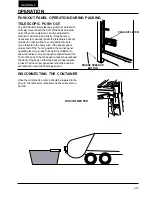

DISCONNECTING THE CONTAINER

Once the container is empty, it should be lowered to the

ground, the latch arms released and the cable discon-

nected.

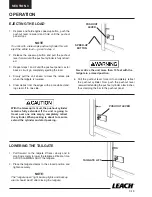

DISCONNECTED

PUSHOUT LEVER

ENGINE SPEED UP

BUTTON

3-16

Summary of Contents for 2R-II

Page 1: ...2RII PACKMASTER OPERATORS MANUAL Over Serial Number 16000 BUILDING THE BEST...

Page 2: ......

Page 11: ...1 6 SAFETY PRECAUTIONS SECTION 1 1 4 2 5 6 3 7 8 9 10 7 7 9 1 8 4 5 2 6 10 1 3 1 6...

Page 12: ...SAFETY PRECAUTIONS SECTION 1 2 1 3 4 5 1 2 3 4 5 1 7...

Page 14: ...SAFETY PRECAUTIONS SECTION 1 11 12 13 14 15 16 17 18 19 20 21 22 23 1 9...

Page 16: ...SAFETY PRECAUTIONS SECTION 1 1 11...

Page 17: ......

Page 25: ......

Page 27: ...OPERATION SECTION 3 LOCATION OF OPERATING CONTROLS 1 2 3 8 9 10 11 12 7 4 5 6 7 8 3 2...

Page 46: ......

Page 48: ......

Page 49: ......