Superabrasive

User

Manual

Original

Language

Lavina®

25LM

‐

S

‐

E

12/2014

13

8.

MAINTENANCE

AND

INSPECTION

CLEANING

Keep

your

machine

clean.

Cleaning

the

machine

on

a

regular

basis

will

help

detect

and

solve

potential

problems

before

they

can

cause

damage

to

the

machine.

Most

importantly,

check

and

clean

the

tool

plate

connections,

power

cord

and

plugs,

vacuum

hoses,

and

water

tank.

CHECK

DAILY

After

operating

the

Lavina

S

machine,

the

operator

should

conduct

a

visual

inspection

of

the

machine.

Any

defect

should

be

solved

immediately.

Pay

attention

to

power

cords,

plugs

and

vacuum

hoses,

loose

bolts

or

screws.

Tool

holders:

Buffers

and

spiders

are

consumables

and

must

be

visually

checked

every

day

and

replaced

when

needed.

Make

sure

flanges

and

discs

are

mounted

and

locked

well

in

place.

The

key

lock

holders

(butterflies)

should

be

checked

also.

Check

the

rubber

buffers

and

the

fixing

of

the

holdings.

The

flange

holding

the

buffers

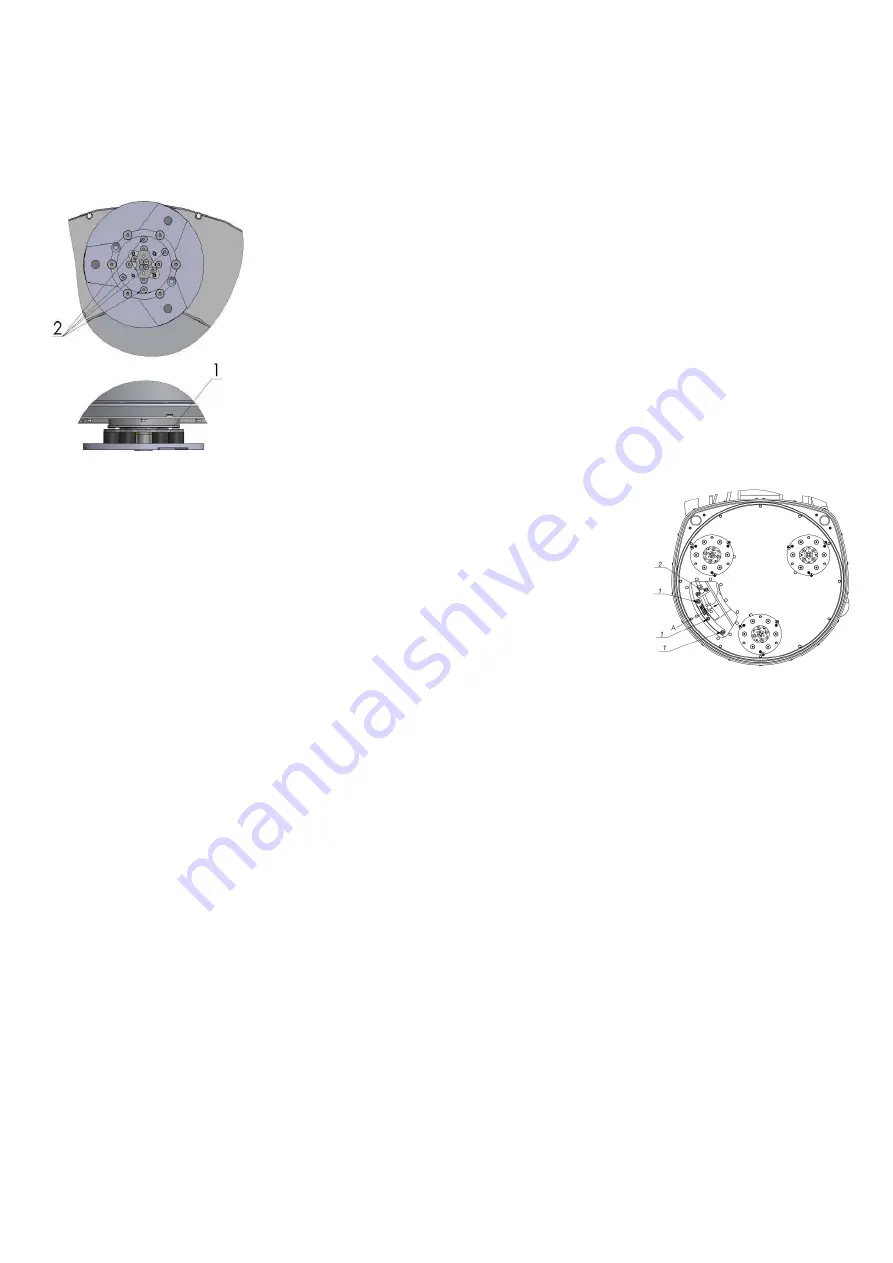

(Fig8.1

1)

has

to

be

firmly

fixed

to

the

unit.

A

gap

seen

there

means

that

there

are

loose

screws

securing

the

holder.

The

screws

have

to

be

tightened

immediately

to

safely

operate

the

machine.

Working

with

loose

screws

on

the

holder

could

also

cause

damage

to

the

machine.

The

tightening

force

of

the

screws

has

to

be

25…

30N.m

(18…22

ft/lbs).

It

is

very

important

to

regularly

check

the

screws

(Fig.8.1

2)

that

fix

the

“QuickChange”

holder

to

the

safety

part,

so

that

the

holder

will

not

fly

away

if

the

buffers

get

damaged.

The

tension

of

the

planetary

belt

can

be

checked

daily

by

moving

the

head

and

feeling

the

resistance

of

the

moving

pulleys,

if

the

belt

slips

tension

immediately,

see

the

chapter:

Troubleshooting.

CHECK

AND

REPLACE

AFTER

THE

FIRST

15

WORKING

HOURS

Check

the

belt

tension

after

15

hours

of

working

with

the

machine.

The

bottom

cover

has

a

control

cover

(Fig.8.2)

that

allows

for

fast

and

easy

control

and

correction

of

the

belt.

It

is

recommended

that

the

tension

of

the

belt

be

tested

after

the

first

15

hours,

and

tightened

if

necessary.

For

the

correct

tension,

see

the

chapter:

TROUBLESHOOTING

“mounting

the

belt”.

Every

time

you

open

the

control

cover,

mount

all

the

screws

back

with

washers.

CHECK

EVERY

200

WORKING

HOURS

Every

200

working

hours,

the

operator

should

inspect

all

parts

of

the

machine

carefully.

Most

importantly,

inspect

and

clean

the

tool

plate

connections,

power

cords

and

plugs,

vacuum

hoses

and

the

water

tank

filter.

Also,

check

the

water

flow

of

the

pump.

Check

the

guard

assembly.

Make

certain

that

the

wheels

are

clean

and

are

rotating

properly.

Inspect

the

control

buttons.

If

there

are

defective

control

parts,

they

should

be

replaced

immediately.

Replace

worn

vacuum

and

water

hoses.

Check

the

tension

of

the

belt

and

tighten

it

when

necessary.

For

the

correct

tension

see

the

chapter,

TROUBLESHOOTING.

Dismount

the

tool

holders

(see

TROUBLESHOOTING)

replace

all

parts

(spider,

buffers,

sealer

caps,

“O”

rings)

with

the

slightest

damage.

Open

the

inspection

cover

on

the

motor

base

to

check

on

the

planetary

driving

belt;

by

moving

the

main

head,

the

belt

should

not

slip

on

the

planetary

pulley

and

drive

the

pulleys.

CHECK

EVERY

400

WORKING

HOURS

Besides

the

checks

of

200

working

hours,

replace

the

sealer

and

V

‐

rings

like

described

in

the

chapter:

TROUBLESHOOTING,

replacing

belt

and

pulley

units.

Check

is

the

belts

and

bearings

are

in

good

condition,

change

if

needed.

VACUUM

As

previously

stated,

frequently

check

hoses

and

other

parts

for

clogging.

WATER

LEAKS

Replace

any

leaking

parts

immediately

as

the

water

could

damage

your

machine.

MECHANICAL

PARTS

Parts

such

as

the

belts,

seal

rings,

spiders

and

buffers,

and

guard

assembly

are

subject

to

wear

and

should

be

replaced

as

needed.

ELECTRICAL

SYSTEM

Dust

should

not

enter

the

control

box,

as

it

will

destroy

the

contacts.

Remove

(blow

out)

any

dust

present.

Figure 8.2

Figure 8.1