9. INSPECTIONS AND MAINTENANCE

9.1. Periodical inspections

Every week check the boiler pressure using the machine

pressure gauge.

Note

The boiler pressure must be 0.8-1.2 bar.

Every four months check the gaskets of the brewing unit

(for brewing unit disassembling see the section 9.2.1).

Every year check the correct operation of the discharge-

on-way valve (for checking procedure see the section

9.2.2.).

Every year check the correct operation of the pressure

gauge.

Every year check for possible lime scale build up on the

heating element and boiler.

Every year check the efficiency of the solenoid valve of

the brewing unit.

Every year check for possible water leaks on the bench

and the condition of the discharge devices.

9.2. Routine and supplementary maintenance

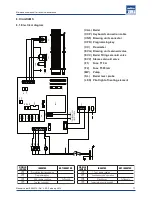

9.2.1. Brewing unit

To replace the brewing unit components proceed as fol-

lows:

- loosen the screw (A);

- remove the spring (B);

- replace the perforator (C), if damaged, (not compliant

dispensing);

- loosen the ring (D);

- replace the gasket (E);

- replace the gasket (F);

- replace the internal gasket (G).

9.2.2. Discharge-one-way valve

Check the discharge one-way valve as follows:

- activate the brewing unit for at least 30 seconds;

- attach a capsule-holder (1) with pressure gauge (avai-

lable on demand) to the brewing unit;

- activate the brewing unit and check the pressure in-

crease until 8-9 bars via the pressure gauge (2);

- check the pressure increase due to the expansion ef-

fect of the heated water until approximately 12 bar:

when this value is reached there is the confirmation of

the correct operation of the valve and the sealing of the

gaskets and solenoid valves.

G

F

D

E

B

C

A

1

2

Manual code 10066574 / Rel. 2.00 / February 2012

19

Maintenance manual for technical assistance