OPERATING INSTRUCTIONS

3-19

Third Axle Flip Operation

(Option)

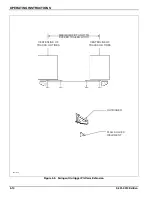

Flip Axle Up

1.

To flip from road position, use the manual height

control to raise rear of trailer

Control Operating Instructions (825 and 835 Ag

(Tail Plate)” on page 3-16 and “Operating

Instructions (835 Construction) (Curbside

Bolster)” on page 3-17.)

2.

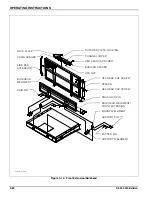

Turn switch for flip axle air bags to the “OFF” position.

This will allow flip axle to settle down for easy

removal of flip axle lower retaining pins

NOTE

“ON” position is for road use of flip only.

3.

Remove lower retain pins and place in pin storage

location.

DANGER

4.

Flip the axle up:

a.

For manual operation, use d-ring on bottom of

flip axle bumper to attach chain from lifting

device (overhead crane, loader, excavator, etc.)

to lift and flip the flip axle assembly over onto the

trailer frame /trunnion bed.

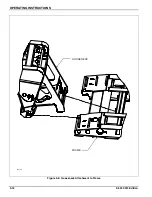

b.

For hydraulic operation, with gooseneck attached

to main frame and hydraulic lines for flip coupled

at the gooseneck, operate the auxiliary hydraulic

control lever to flip the flip axle assembly over

onto the trailer frame/trunnion bed.

5.

Disconnect flip axle electrical harness from trailer

frame and shut off air supply to brake chambers (red

and white couplers).

6.

Return trailer to normal ride height.

a.

On AG trailer, turn manual height control switch

to “OFF” position.

b.

On Construction trailer, return control handle to

normal ride position.

Flip Axle Down

1.

Reconnect flip axle electrical harness to trailer frame

and turn on air supply to brake chambers (red and

white couplers).

2.

To flip to road position, use the manual height control

to raise rear of trailer

Operating Instructions (825 and 835 Ag (Tail

Plate)” on page 3-16 and “Operating Instructions

(835 Construction) (Curbside Bolster)” on

page 3-17.)

3.

Check that switch for flip axle air bags is in “OFF”

position. This will allow flip axle to settle down for

easy installation of flip axle lower retaining pins

4.

Double check that lower retain pins are removed.

DANGER

5.

Flip the axle down for road position:

a.

For manual operation, use d-ring on bottom of

flip axle bumper to attach chain from lifting

device (overhead crane, loader, excavator, etc.)

to lift and flip the flip axle assembly over to road

position.

b.

For hydraulic operation, with gooseneck attached

to main frame and hydraulic lines for flip coupled

at the gooseneck, operate the auxiliary hydraulic

control lever to flip the flip axle assembly over to

road position.

6.

Reinsert lower retain pins.

7.

Turn switch for flip axle air bags to the “ON” position.

This will allow flip axle air bags to inflate and operate

with trailer height control. The flip axle lower retaining

pins are now tight.

8.

Return trailer to normal ride height.

a.

On AG trailer, turn manual height control switch

to “OFF” position.

b.

On Construction trailer, return control handle to

normal ride position.

Stand clear of flip axle during flip operation.

Stand clear of flip axle during flip operation.

Summary of Contents for 825D Series

Page 2: ......

Page 6: ...iv F 691 0913 Edition...

Page 14: ...2 6 F 691 0913 Edition STANDARD SPECIFICATIONS...

Page 40: ...3 26 F 691 0913 Edition OPERATING INSTRUCTIONS Page Intentionally Blank...

Page 60: ...4 20 F 691 0913 Edition MAINTENANCE AND LUBRICATION Figure 4 13 Axle and Brake Assembly...

Page 77: ...TROUBLESHOOTING GUIDE 5 9 Notes...

Page 78: ...5 10 F 691 0913 Edition TROUBLESHOOTING GUIDE...

Page 79: ......