4-10.4

Replace the hub and drum as follows

a.

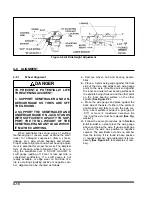

For outboard mount hub and drum remove

the brake drum

(See Figure 4-14)

. It may be

necessary to release the slack adjuster. For

inboard mount,

(See Figure 4-15)

remove

drum after hub.

b.

Remove hub cap and catch lubricant in a

pan.

c.

Remove outer spindle nut, spindle locking

washer, inner spindle nut, and bearing. Re-

move hub from axle.

d.

Using an appropriate driver, remove inner

bearing cone, and seal.

e.

Using an appropriate driver, remove bearing

cups from hub.

f.

Check that the hub cavity is clean. If the hub

is to be reused, clean it thoroughly.

g.

Insert bearing cups into the hub.

h.

Install the drum to the hub or wheel unless

the drum is outboard mount.

i.

Clean the mounting surfaces with a good

grade commercial cleaner and soft rag. Dry

all component parts with a clean, absorbent

cloth or paper. Lubricant will not adhere to

surfaces wet with solvent.

j.

For hub and drum, make sure the drum

seats flat against the hub flange and mates

properly with the hub pilot. There should be

no interference between the brake drum pilot

chamfer and the corner radius on the hub.

k.

Install inner bearing, cone, and seal.

IMPORTANT

DO NOT MIX NEW CUPS WITH OLD CONES OR

NEW CONES WITH OLD CUPS.

l.

If studs are marked “R” or “L”, right hand (R)

hubs should be installed on the curbside of

the vehicle, left hand (L) hubs should be in-

stalled on the driver side.

DANGER

FAILURE TO USE THE CORRECT

STUD ON THE CORRECT SIDE MAY

CAUSE LOOSENING OF THE HUB

STUDS DURING OPERATION, RE-

SULTING IN LOSS OF A WHEEL.

m.

Place the hub or wheel over the axle spin-

dle being careful to align the hub bore with

the axle. Do not damage the seal. Support

the hub assembly until the outer bearing cone

and spindle nut are installed, to avoid damag-

ing the seal.

n.

Install the outer bearing cone and inner

spindle nut, tightening the nut until it is snug

against the outer bearing cone. Remove the

hub support allowing the hub to rest on the

bearings.

o.

Install and adjust bearings

(See Wheel

Bearing Lubrication and Adjustment).

p.

Install the hub cap with the proper gasket.

Tighten the cap screws of the hub cap to 15

to 20 ft-lbs. of torque.

q.

Remove the filler plug and fill the hub cavity

to the recommended level with a gear type

oil.

r.

For Outboard Mounted Brake Drum

(See

Figure 4-14)

place the drum over the hub and

brake shoes being careful not to damage the

threads on the studs. Make sure the drum

seats flat against the hub flange and mates

properly with the hub pilot. There should be

no interference between the brake drum pilot

chamfer and the corner radius on the hub. If

interference exists, the hub will not be able to

function properly.

4-21

Summary of Contents for 336C

Page 3: ...MODEL 336C CAR CARRIER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO...

Page 8: ......

Page 24: ...3 12 Figure 3 7 Lining Up the Over the Cab Deck Figure 3 8 Loading the Over the Cab Deck...

Page 28: ...3 16 Figure 3 11 Loading the Lower Deck...

Page 32: ...3 20 Figure 3 13 Rear Impact Guard and Antilock Brake System...

Page 40: ...4 6 Figure 4 3 336C Wiring Diagram...

Page 45: ...4 11 Figure 4 7 Checking Axle for Bend Figure 4 8 Examples of Camber...

Page 50: ...4 16 Figure 4 12 Axle and Brake Assembly...

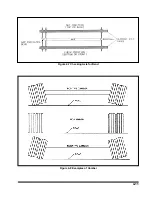

Page 54: ...4 20 Figure 4 14 Outboard Mount Hub and Drum Figure 4 15 Inboard Mount Hub and Drum...

Page 59: ...4 25 Figure 4 19 Mounting Tires and Wheels Figure 4 20 Stud Tightening Sequence...

Page 70: ...NOTES 5 10...