Installation and adjustament manual

21/26

PROGRAMMATION

maximum.

E) IDLE ENRICHMENT: this parameter allows

modification of the fuel enrichment during idle

condition, and it can be modified by +/- 20 steps

maximum.

F) DISABLE/ENABLE ADAPTIVE LEARN: This

button is used to activate or deactivate the

ADAPTIVE LEARN STRATEGY.

G) RESET MODIFICATIONS: This button zeros all

the modifications that have been entered; that is, it

deletes both the changes performed by the Adaptive

Learn and the manual corrections performed as in (B).

H) ENTER CHANGES: It transmits all the entries of

the Adaptive Learn screen to the ECU.

5.7.4.1 Operational principles

During its operation, the LIS calculates a correction factor

to the mapped strategy by processing the signal from the

Lambda sensor. This is then actuated by the actuators.

This correction factor is called INTEGRATOR (paragraph

6.5.2). The LIS performs the above-mentioned operation

to adapt itself to the vehicle’s characteristics, i.e. mileage,

spark plug conditions, air filter, fuel chemical composition,

etc.

The LIS ECU calculates an average of the applied

correction factor (INTEGRATOR), subdivided by RPM

range. This is displayed in the screen ADAPTIVE LEARN

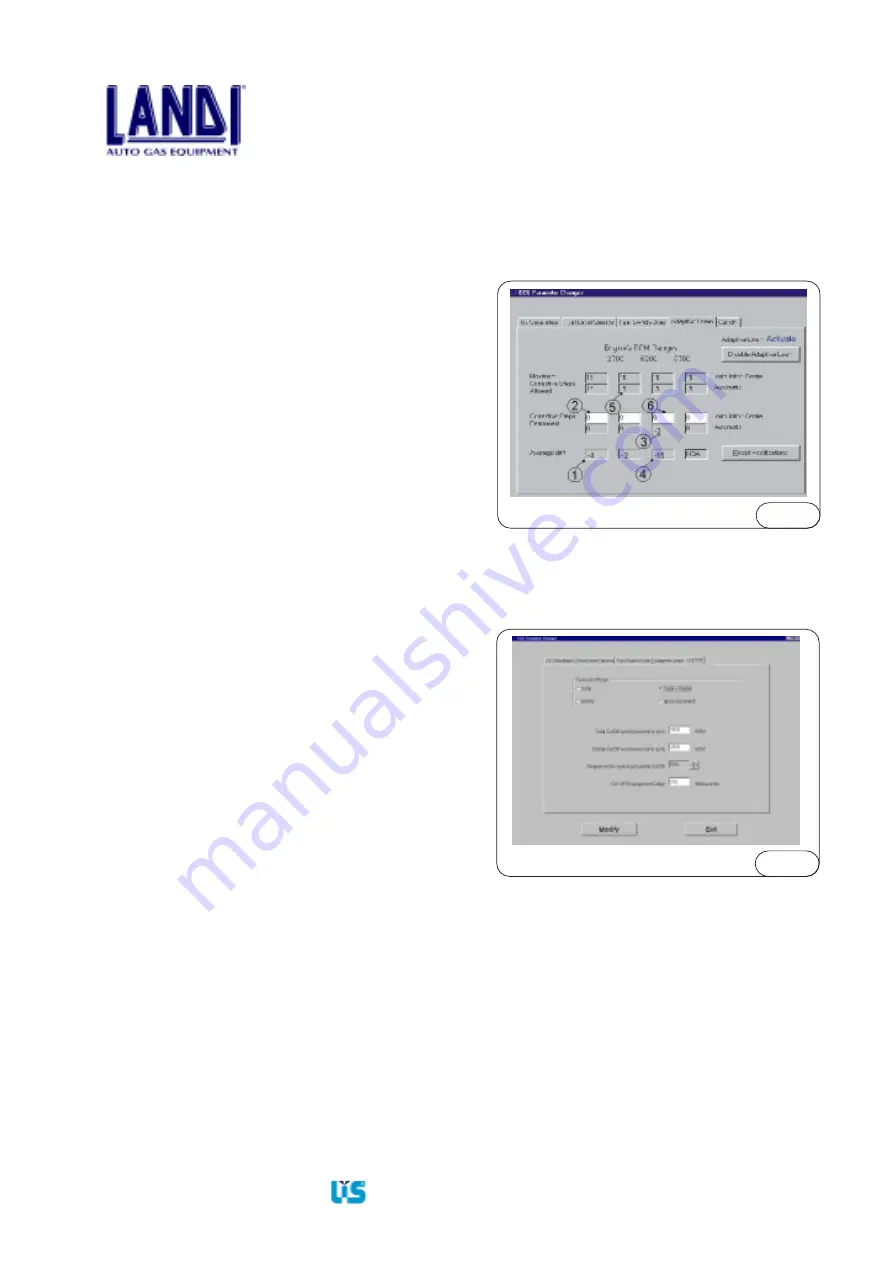

at the item AVERAGE DRIFT (C). See Fig. 5.9.

5.7.4.2 Automatic correction

The value AVERAGE DRIFT (C), see Fig. 5.9, is used by

the automatic Adaptive Learn to set up a correction factor

that can be seen in the cell CORRECTIVE STEPS

PERFORMED, at the AUTOMATIC line (B). The value

in the CORRECTIVE STEPS PERFORMED cell is

algebraically summed to the value programmed in the map.

5.7.4.3 Manual correction

The values in the AVERAGE DRIFT cells show by how

much the carburetion must be further corrected, in the

event that the corrections performed by the automatic

Adaptive Learn are not sufficient. To this end, it is possible

to enter the value of the AVERAGE DRIFT cells in the

cell CORRECTIVE STEPS PERFORMED, INSTALLER

line, in the appropriate RPM range.

Example:

If a condition similar to the one in Fig. 5.10 occurs, the

AVERAGE DRIFT (1) value of the first range may be

inserted in the cell CORRECTIVE STEPS PERFORMED,

at the INSTALLER line (2); the same operation can be

performed for the 1,300 and 3,000 RPM range.

For the 3,000-5,300 RPM range, the Adaptive Learn has

already performed -2 corrective steps (3), since the

AVERAGE DRIFT (4) has exceeded the value of cell

MAXIMUM MODIFICATION STEPS PERFORMED,

at the AUTOMATIC (5) line. The possible manual

correction is to enter the value of -15 steps AVERAGE

DRIFT (4) in the cell (6) CORRECTIVE STEPS

PERFORMED.

The above description is just an example: the values and

the set-ups are solely to illustrate the procedure to be

followed in order to perform corrections.

5.7.5 CutOff

In this section, Fig.5.11 it is possible to choose the type of

cutoff and set the correct parameters to close the gas during

deceleration.

TYPE OF CUTOFF:

Fig.5.10

TOTAL: Selecting this parameter, the system work on

cutoff valve and close completely the passage of gas until

the number of RPM set on the cell “TOTAL CUTOFF

END”.

It is also possible to set in the apposite cell the “CUTOFF

ENGAGEMENT DELAY”.

PARTIAL: Selecting this parameter, the system work on

steps motors and close partial the passage of gas until the

number of RPM set on the cell “PARTIAL CUTOFF

END”. It is possible to choose on the apposite cell the per

cent “STEPPER-MOTOR OPENING IN PARTIAL

CUTOFF”.

It is also possible to set in the apposite cell the “CUTOFF

ENGAGEMENT DELAY”.

Fig. 5.11