LANDA SEHW • 8.913-932.0 • Rev. 02/12a

11

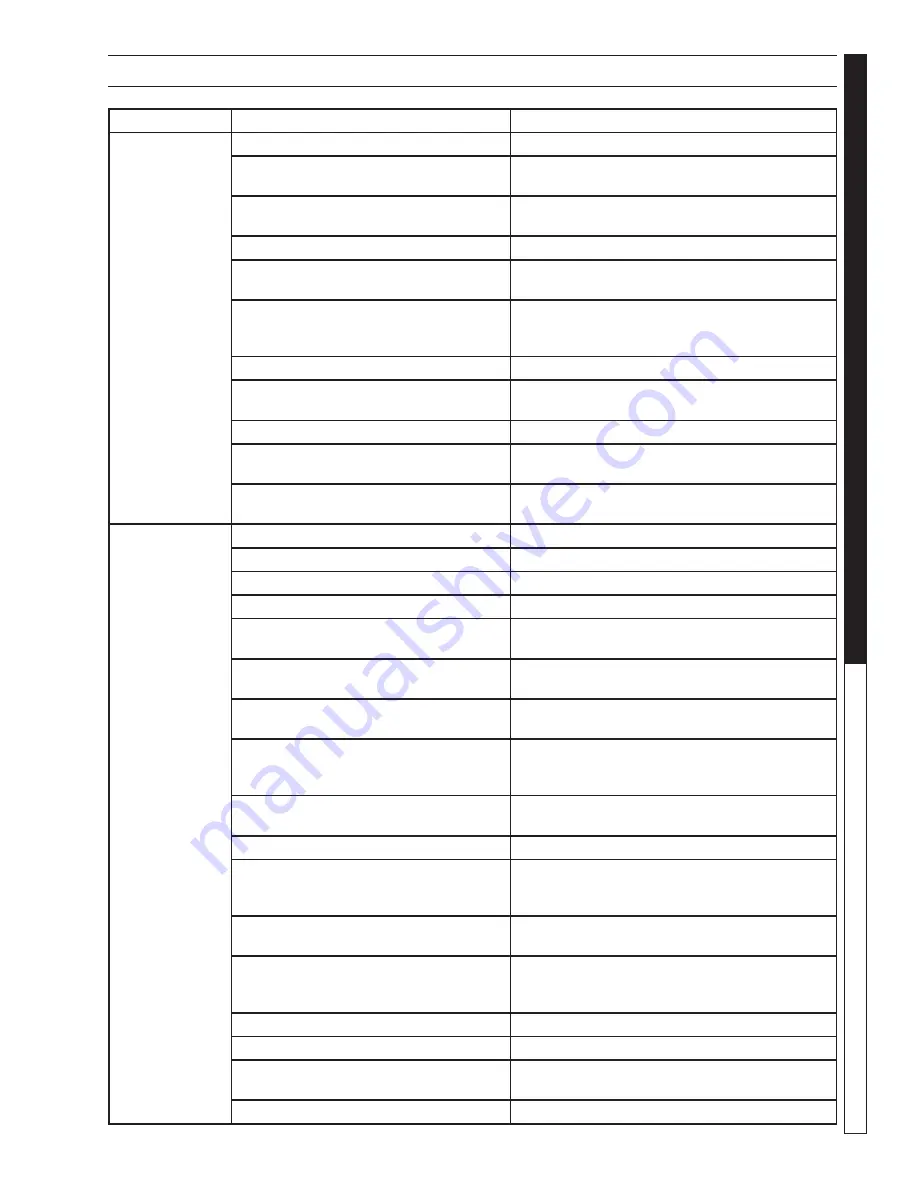

PRESSURE

W

ASHER

Tr

oub

leshooting Guide

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

LOW

OPERATING

PRESSURE

Faulty pressure gauge

Test with 2nd gauge. If bad install new gauge.

Insufficient water supply

Use larger garden hose; clean water filter at

inlet. Clean screen inside float tank.

Old, worn or incorrect spray nozzle

Match nozzle number to machine and/or

replace with new nozzle.

Belt slippage

Tighten or replace; use correct belt.

Plumbing or hose leak

Check plumbing system for leaks. Retape

leaks with teflon tape.

Faulty or mis-adjusted unloader valve

(Where applicable)

Adjust unloader for proper pressure. Install

repair kit when needed. Test PSI with unloader

removed, taking pressure directly off the pump.

Worn packing in pump

Install new packing kit.

Fouled or dirty inlet or discharge valves

in pump

Clean inlet and discharge valves.

Worn inlet or discharge valves

Replace with valve kit.

Low power supply

Check voltage of building and compare with

requirements. Obtain a different power source.

Detergent metering valve left open

sucking air, or faulty metering valve

Close and/or replace metering valve.

BURNER WILL

NOT LIGHT

Little or no fuel

Fill tank with fuel.

Improper fuel or water in fuel

Drain fuel tank and fill with proper fuel.

Plugged fuel filter

Replace as needed.

Misadjusted burner air bands

Readjust air bands for clean burn.

Little or no fuel pressure from fuel pump Increase fuel pressure to specification on fuel

pump and/or replace fuel pump.

Faulty burner transformer

Test transformer for proper arc between

contacts. Replace as needed.

Disconnected or short in electrical

wiring

All wire contacts should be clean and tight.

No breaks in wire.

Burner motor thermal protector tripped

If tripped, check voltage, connections, and

extensions for cause. Check fuel pump shaft

rotation for binding causing motor to overheat.

Flex-coupling slipping on fuel pump

shaft or burner motor shaft

Replace if needed.

On-Off switch defective

Check continuity through burner switch.

Heavy sooting on coil and burner, can

cause interruption of air flow and

shorting of electrodes

Clean as required.

Improper electrode setting

Clean and set according to

diagram in Operators Manual.

Fuel not reaching combustion chamber

Check fuel pump for proper flow. Check

solenoid flow switch on units with spray gun

control, for proper on-off fuel flow control.

Clogged burner nozzle

Replace.

Water not flowing through unloader

Open spray gun to allow water to flow.

Flow switch malfunction

Remove test for continuity and replace as

needed.

Fuel solenoid malfunction

Replace if needed

Summary of Contents for SEHW6-3500

Page 36: ......

Page 38: ...Form 8 913 932 0 Revised 02 12a Printed in U S A...