Section 1: Assembly & Set-up

RC5610, RC6610, RCM5610, & RCM6610 Series 2 S/N Rotary Cutters 330-539M

5/6/20

26

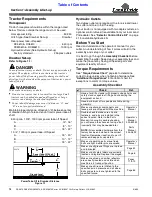

Lift Cylinder Mount Position

Refer to Figure 1-22:

Lift cylinder (#1) should be mounted in lower hole (A) if

cutter is equipped with 21" laminated tires or middle

hole (B) if cutter is supplied with 25.5" aircraft tires, or

upper hole (C) if 29" aircraft tires. Reposition lift cylinder

if it is not assembled in the correct hole.

1. Park tractor and cutter on a level surface and raise

center deck fully up.

2. Without lowering cutter, shut tractor down properly

before dismounting. Refer to

3. Place sturdy support blocks or jack stands under the

four corners of the center deck.

4. Remove all stroke control spacers (#4) from the

cylinder rod.

5. Start tractor and lower center deck onto the support

blocks until hydraulic cylinder hitch pin (#2) is loose.

6. Shut tractor down properly before dismounting.

7.

Remove hairpin cotter (#3) and hitch pin (#2).

8. Reposition hydraulic cylinder to the correct mounting

hole (A, B, or C) and reinsert hitch pin (#2). Secure

hitch pin with hairpin cotter (#3).

9. Start tractor, raise deck fully up, and properly shut

tractor down again before dismounting.

10. Replace stroke control spacers (#4) and remove

support blocks.

11. Start tractor and cycle hydraulic system by raising

and lowering center deck cylinder and wing folding

cylinders.

Adjust Light Kit

Refer to Figure 1-23:

The Light Kit will need to be adjusted when purchased

assembled to the cutter at the factory.

Adjust light kit as follows:

1. Shut tractor down properly before dismounting. Refer

to

2. On the right-hand wing, loosen hex locknuts (#1). Do

not remove locknuts.

3. Slide light assembly (#2) and mounting clamp (#3) as

far as possible toward the rod end of hydraulic

cylinder (#4).

4. Tighten each locknut (#1) one-half turn in a criss-

cross pattern until all nuts are tightened to the correct

torque.

Lift Cylinder Mount Position

Figure 1-22

Adjust Light Kit

Figure 1-23

Hook-up LED Lights

Refer to Figure 1-25 on page 27:

The lead wiring harness (#13) is equipped with a 7-way

round pin connector for connecting to the tractor’s 7-pin

electrical outlet shown in Figure 1-26 on page 27.

1. Route lead wire harness (#13) through spring hose

loops (#10).

2. Connect lead wire harness (#13) to the tractor’s

7-way round pin receiver.

3. It is best to have a second person verify the lights are

operating. Start tractor and operate lights as follows:

a. Turn on head lights to verify red lights illuminate.

b. Turn on flasher lights to verify amber light are

blinking on and off.

4. If the lights did not operate properly, recheck hook-up

of enhance module and wire harnesses. Make

necessary changes and repeat step 3 above.

5. Check wire harness routing to make sure wires will

not be pinched as the wing is folded and unfolded

and while raising and lowering cutter height.

6. Add cable ties to wire harness as needed to secure

the harnesses in place.

37840

37658a