4 PRINCIPLES OF OPERATION

4.1 GENERAL

This supply rectifies and filters the AC input voltages, then a 20kHz switching buck

regulator regulates the output DC. Also supplied is a 25kV ignition pulse and 800V boost

to start the lamp. The A100 PCB compares the output current to the input reference and

adjusts the duty cycle up or down to maintain regulation.

Figure 5 Duty Cycle Regulation

4.2 POWER FLOW (SCHEMATIC 01-475-005)

The 208/220 VAC 3 Phase or 208/220 VAC 1 Phase power is applied to TB1 then to CB1

and on to the line filter A300. From the line filter, the AC is rectified by CR4, (CR4a and

CR4b for 1 Phase), and is filtered by L1 and C1, (L1a, L1b, C1a, C1b and C1c for 1

Phase P/S). The resulting DC is then chopped by the buck converter A200 and again

filtered by L2 & C2. CR5 is a blocking diode, which allows the injection of a boost voltage

and T1 is the ignition transformer, which produces the 25kV start pulse.

4.3 SIGNAL FLOW (SCHEMATIC 01-000-225)

The 208 VAC is applied to T3 & T4, which reduces the voltage to 15 VAC, which is

rectified by CR45, CR49, CR47 and filtered by C33, C35 and C37. U12, U13 and U14

regulate the rectified DC to produce three independence DC voltages, which supply the

control circuit with operating potential.

The main PWM is U8 and its' output is via P4, Pins 4 & 5. The control amplifier (Pins 1 &

2) is connected to the shunt and provides for current regulation. The control amplifier

(Pins 4 & 5) is connected to the attenuated voltage output and provides for the maximum

unloaded voltage output.

Pin 9, the shutdown pin, is controlled by U7, which in turn is controlled from the protection

circuits U1, U3 and U4. U5A, U6, T2 & U10B isolate the control signal which is used to

unbalance the inputs to the PWM (Pins 1 & 2).

The shunt voltage is amplified by U10A and fed to the isolation circuits of U11, T1 and

U4B. This channel allows the output DC current to be monitored by an external monitor

isolated from the DC shunt.

Page 13 of 18

83-475-001 Rev. D

Summary of Contents for ESKI

Page 6: ...Figure 1 Loss Pass Filter Page 4 of 18 83 475 001 Rev D...

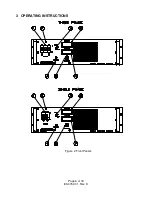

Page 8: ...3 OPERATING INSTRUCTIONS Figure 2 Front Panels Page 6 of 18 83 475 001 Rev D...

Page 11: ...Figure 3 1 Phase Front Panel Control Hookup Page 9 of 18 83 475 001 Rev D...

Page 14: ...Figure 4A 1 Phase External Control Hookup Page 12 of 18 83 475 001 Rev D...