INSTALL AND CONNECT WATER SUPPLY LINES

Furnishing and plumbing the water supply lines is the responsibility of the owner and/or

installer. This section explains the plumbing layouts recommended by the Manufacturer.

When installing and connecting the water supply lines to the Oven/Steamer, observe the

following guidelines and instructions.

The Oven/Steamer has compression fittings at the back of the unit for connection to the

water supply lines.

The steam generator and humidifier

fitting (

on dimension drawing)

is 3/4” IPS and the

condenser and boiler rinsing

fitting (

on dimension drawing) is 3/4”

IPS.

Always connect untreated COLD water supply to the Oven/Steamer condenser/boiler rinsing

water supply line. DO NOT USE HOT WATER. The Oven/Steamer will not function properly or

within design safety limits if hot or warm water is supplied.

Do not connect the to a softened or treated water supply which adds chlorine or chloride

salts to the water. Refer to the Softened, Treated, or Filtered Water instructions on page 21

for details.

Supply water must have a minimum dynamic pressure of 35 psi (2,4 kg/cm

2

) and a maximum

static pressure of 60 psi (4.1 kg/cm

2

). Water pressure greater than 60 psi will cause damage

to the solenoid valves. Local water pressure can be 100 psi or more.

If possible, check supply pressure at non-peak demand time. A local water company can

assist in this check. If static pressure exceeds 60 psi water, a pressure regulator must be

installed in the supply lines. For best results, set the regulator for 50 psi dynamic pressure.

Refer to the recommended plumbing layouts in Figures 2-6 and 2-7, and install the water

supply lines and fittings in accordance with all local and national codes.

While constructing and installing the water supply lines, pay particular attention to the

following requirements and recommendations.

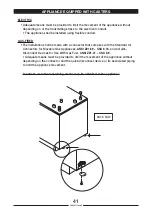

Figure 2-6. Water Supply Lines without a water trattament system

48

90028771rev00

WATER CONNECTION

ON DIMENSION

DIAGRAM

PRESSURE REDUCER

(IF REQUIRED)

AIR/WATER COLUMN

(IF REQUIRED)

40-MESH STRAINER

CHECK VALVE

MAIN WATER

SHUT-OFF VALVE

SOFTENED COLD/HOT

(MAX 122

ϒ

F/50

ϒ

C)

WATER SUPPLY

WATER CONNECTION

ON DIMENSION

DIAGRAM

PRESSURE REDUCER

(IF REQUIRED)

AIR/WATER COLUMN

(IF REQUIRED)

40-MESH STRAINER

CHECK VALVE

MAIN WATER

SHUT-OFF VALVE

MAIN UNTREATED

COLD

WATER SUPPLY

Oven/Steamer

CONDENSER

STEAM GENERATOR

RINSING

STEAM GENERATOR

FILLING UP

HUMIDIFIER

1

-

2

-

3

-

4

-

5

-

WARNING

This equipament is to installed with adeguate BACKFLOW that complies with

FEDERAL, STATE, OR LOCAL CODES having jurisdiction

Summary of Contents for Naboo Compact CBEN061

Page 2: ... 2 90028771rev00 ...

Page 20: ... 20 90028771rev00 INSTALLATION DIAGRAMS ...

Page 64: ... 64 90028771rev00 ...

Page 65: ... 65 90028771rev00 65 90028771rev00 ...

Page 66: ... 66 90028771rev00 66 90028771rev00 ...

Page 67: ......