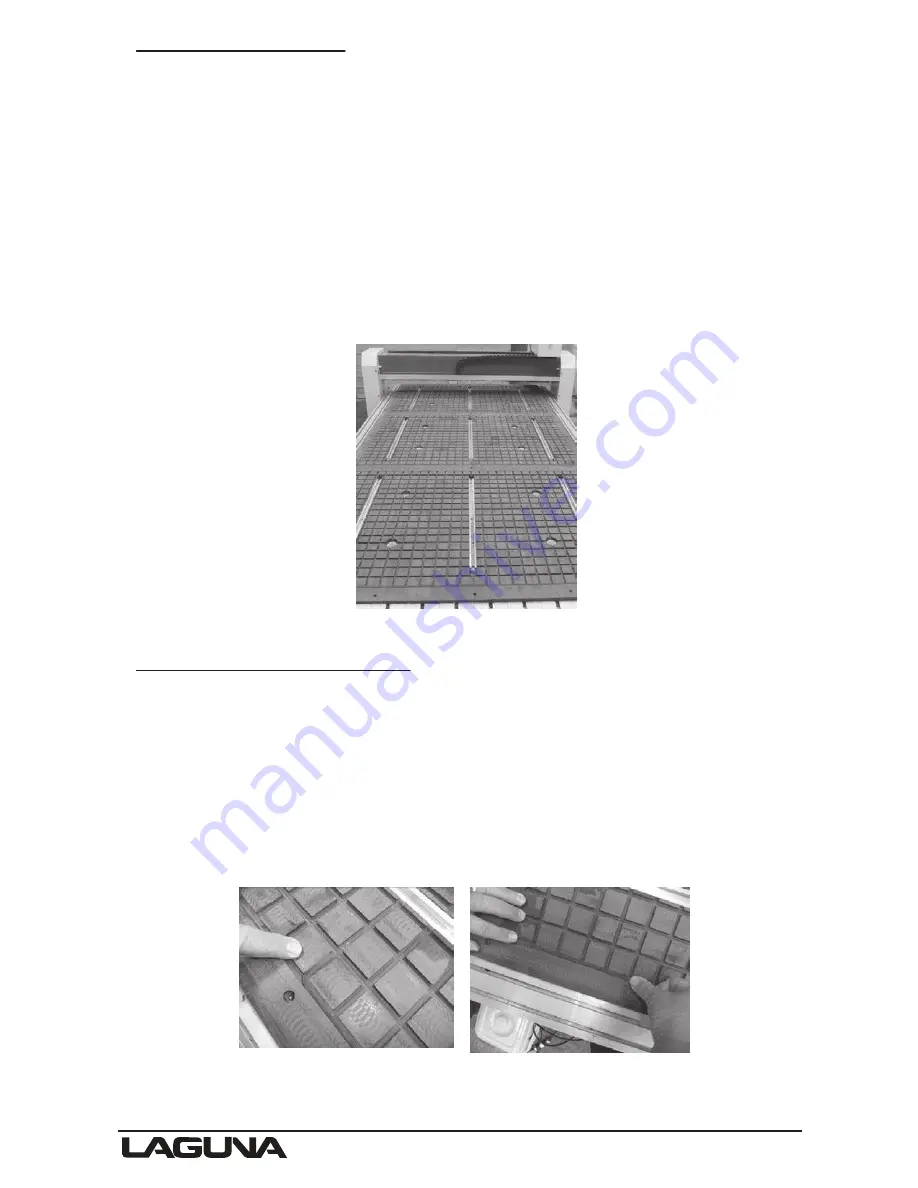

Vacuum table

Start point foam rubber

gasket turned in

Inserting foam rubber gasket

Using the Vacuum Table

Note: The better the vacuum created, the more securely the parts will be

held in place. Follow the below instructions to obtain optimum results.

The vacuum table has 6 zones and you can set the configuration to suit the type

of work that you will be producing. Each zone is controlled by a switch that is

located at the front of the machine. The table has two holes in each zone that

extract the air and generate the vacuum. The table has grooves that ensurethe

air is extracted evenly across the zone. To seal the zone from leakage, a foam

rubber gasket is pressed into the outer grooves. This gasket sits slightly proud of

the table and is compressed by the spoil board [sometimes called sacrificial

board] as the vacuum is applied. T slots are also provided to allow you to clamp

jobs / spoil boards to the table should it be required.

Fitting the Foam Rubber Gasket

It is important that the foam rubber gasket is pressed evenly into the grove in the

vacuum table around the zone that you are constructing. To ensure a good seal,

it is strongly recommended that the gasket is turned in at the beginning [as

shown]. The gasket has a tendency to stretch while fitting and over time it may

relax and shorten. The extra length of gasket allows you to re-set it and make the

seal again. If the initial turn is not put in place, there is no margin for error and

you may have to discard a complete length just for being one inch short.

It is recommended that you initially create 3 zones, each one completely across

the table. You can change the configuration at a later stage.

19

Summary of Contents for Laguna Series

Page 2: ......