-16-

www.igmtools.com

Bevel ripping is performed the same as ripping

but with the saw blade set to an angle not

perpendicular with the table surface. To tilt the

blade to the left, anywhere between 0° and 45°.

This is used most often when cutting bevels,

compound mitres or chamfers.

After changing the bevel angle verify the

alignment of the guard and splitter; make sure

there is clearance with the saw blade.

Digital reading calibration

Step 1: Set the wheel perpendicular to the

work table on the scale is 0°, press ZERO to

reset, 0.0 will be displayed..

Step 2: Turn the cast iron wheel to set 45°,

press and hold the SET button.

Step 3: While holding SET, press and hold

ZERO for 3 seconds.

When the ZERO button is released, 45° is

displayed

8.3 Ripping small workpieces

Do not attempt rip cuts if the work piece is

too small, as this will oblige you to place your

hands too close to the blade and put you at

serious risk of injury. When ripping narrower

widths; use a push block or a push stick in

order to avoid placing hands near the blade.

8.4 Cross cutting

Cutting against the grain, to shorten the length

of a board is crosscutting. With some smaller

sized and rectangular pieces, you often have

the choice of ripping or crosscutting. Always

use the mitre gauge, when crosscutting; never

cut a piece unsupported. The mitre gauge may

be used in either slot, but most operators prefer

the left groove for typical work. When the blade

is tilted for bevel cutting, use the table slot that

does not cause interference with your hand or

the saw blade guard.

To begin crosscutting, place the work on the

mitre gauge and, with the motor OFF, slide it up

close to the blade to align the outer edges of

the teeth with your cut mark (see pic).

Keep a firm grip as you pull the mitre gauge

and the wood back away from the blade. Lower

the blade guard, turn on the saw and make the

cut. When the work is cut through, move one or

both cut pieces.

8.5 Angle ruler setting

Stiffness in the groove - for greater rigidity of

the angle ruler in the table groove, there are 2

adjusting screws in the longitudinal profile of

the angle ruler. For greater rigidity in the table

groove, simply tighten the screws more (the

more screws you screw into the profile, the

greater the rigidity). For less rigidity, just loosen

the screws.

Warning: When cross-cutting round stock it

is necessary to secure the workpiece against

rotation by using a suitable jig.

8.5 Bevel cross cutting

This procedure is the same as cross cutting

except that the blade is set to an angle other

than 0. After changing the bevel angle, verify

the alignment of the guard and splitter and

verify that there is clearance with the saw blade.

8.6 Mitre cuts

This operation is the same as cross cutting,

except the mitre gauge is set to an angle. Hold

the work piece firmly against the mitre gauge

and feed the workpiece slowly into the blade to

prevent it from moving during the cut.

Ruler settings

Setting the cutting angle on the ruler - the angle

ruler can be set to + 60 ° - -60 °. By releasing

the ruler handle, you can set the desired cutting

angle by pulling and turning the control knob on

the front of the ruler. Notches are prepared in

the profile for more used angles.

9. Maintenance

To keep you Laguna Tools machine in top

performance for many years please follow

this maintenance schedule and refer to any

instructions.

Daily Check:

• Loose mounting bolts

• Damaged saw blade

• Damaged riving knifes, splitters, or blade

guards

• Worn or damaged wires

• Any other unsafe condition

Weekly Maintenance:

• Clean table surface and mitre slot grooves

• Clean and protect cast-iron table

• Clean rip fence

Monthly Maintenance:

• Clean/vacuum dust buildup from inside

cabinet and off motors.

• Check/replace belt for proper tension, damage

or wear.

Every 6–12 Months:

• Lubricate trunnion slides.

• Lubricate worm gear.

• Lubricate leadscrew.

• Lubricate gearing and gearboxes.

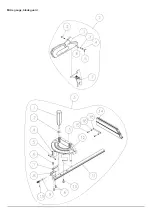

9.1 Internal Components Map

A. Motor

B. Dust Shroud

C. Trunnion Slides (Support)

D. Upper Trunnion

E. Lower Trunnion

F. Arbor Nut

G. Arbor Washer (Flange)

H. Blade

I. Tilt Gearing

J. Height Gearing

K. Belt (behind blade)

L. Worm Screw

M. Tilt Plate

N. Start Capacitor (see spec sheet)

O. Run Capacitor (see spec sheet)

F

G

H

B

E

C

N

A

K

D

C

J

I

M

O

Summary of Contents for Fusion2 2022

Page 2: ...2 www igmtools com...

Page 3: ...3 www igmtools com...

Page 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

Page 19: ...19 www igmtools com Fence assembly...

Page 20: ...20 www igmtools com Mitre gauge blade guard...

Page 21: ...21 www igmtools com Motor and trunnion...

Page 22: ...22 www igmtools com Cabinet...