-12-

www.igmtools.com

7. Adjustments

Your Laguna Tools machine comes fully

adjusted from the factory, but it is good practice

to double check these adjustments and make

sure the tool is in safe operating condition.

7.1 Fence Adjustments

Fitting the fence:

You will need to fit the fence to the right side of

the blade to use the table saw. You will need to

fit the fence to the right side of the blade to use

the table saw.

1. Unplug the table saw!

2. Hold fence with both hands, with cam lock up.

3. Place fence in fence guide

4. Check cam lock action, adjust if necessary.

2. Place fence in fence guide

While holding the fence and the cam lock, raise

the cam lock to engage the open position.

Insert the fence frame into the front rail.

3. Check Cam lock action

The fence can slide freely in any position to the

right of the blade. If the fence does not lock,

adjust both blade paralleling set screws.

Adjusting the Scale (rule):

The scale will need to be “zeroed” every

time the fence guide is taken off the table

or adjusted. The fence must be zeroed for

accurate cuts when using the scale.

1. Unplug the table saw!

2. Position the fence up to blade.

3. Loosen the transparent viewport.

4. Adjust the view as needed.

5. Tighten the view screws.

Place fence in fence guide

WARNING: MAKE SURE SAW IS

UNPLUGGED. With the blade in a high

position, bring the fence close to — but not

touching — the blade. Use a folded piece of

paper between the blade and the fence to

ensure good distance.

Adjust the Viewport

Use a #2 Philips head driver to loosen (but

do not remove) the transparent scale reader.

Adjust the viewport as needed, tighten the

screws. Note: If adjusting the viewport does not

allow enough to zero the scale, see step 8 of

general setup.

There are 2 magnifiers on the longitudinal

ruler, which are used to adjust the width of the

material according to whether you have set the

aluminum profile vertically or horizontally on the

longitudinal ruler.

Adjusting the Fence Glide Bushings:

You may need to adjust the height of the

bushings on either side or rear of the fence. The

fence should be between 1-3 mm off the table

to prevent scratches.

1. Unplug the table saw!

2. Unlock the fence.

3. Use a hex key to adjust the front bushing

height.

4. Use a wrench to adjust the rear bushing

height.

Front Bushings

To adjust the front bushings, use the included

hex key to raise or lower the nylon bushings

that make contact with the front fence rail.

Rear Bushings

Adjusting the Fence to be parallel with the

Blade: It is very important to only operated this

saw with the blade parallel to the fence. Note: If

this section does not help, please see the table

adjustments section: Adjusting the Table to be

Parallel with the Blade. The blade needs to be

parallel to the table (mitre slots) to effectively

make the fence parallel to the blade.

1. Unplug the table saw!

2. Position the fence to access the fence

adjustment screws.

3. Use a hex key to adjust each side

4. Make small increments and check

Use caution: It is not guaranteed that the fence

will be parallel to the saw blade when shipped

from factory. Make sure to make all required

adjustments to make the fence parallel to the

saw blade prior to operation.

Position fence to access adj. screws

WARNING: MAKE SURE SAW IS

UNPLUGGED. Take the fence out of position

and flip it on its back side to access the cat

screws that push the nylon supports in/out.

Use a hex key to adjust

Use the included hex key to adjust the depth of

each nylon support. Do small increments and

check.

7.2 Table Adjustments

Adjusting the Table to be Parallel with the

Blade: It is good practice to make sure that the

table is always parallel to the blade by checking

it often. You can do this with a combination

square or with a dial indicator on an appropriate

mount. Check the IGM website for these tools.

Good

Combination Square. Notice: This method may

leave scratched.

Summary of Contents for Fusion2 2022

Page 2: ...2 www igmtools com...

Page 3: ...3 www igmtools com...

Page 18: ...18 www igmtools com Wiring Diagram Fusion 2 230V...

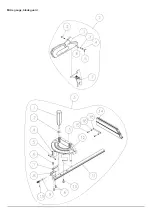

Page 19: ...19 www igmtools com Fence assembly...

Page 20: ...20 www igmtools com Mitre gauge blade guard...

Page 21: ...21 www igmtools com Motor and trunnion...

Page 22: ...22 www igmtools com Cabinet...