5

Removing the rotor

Using an adjustable or 1/4 inch wrench (some units are supplied with a wrench)

loosen the screw and remove the rotor retaining screw/washer assembly by

turning it counterclockwise. Lift the rotor directly upward in a straight vertical

motion.

Caution: Be sure to secure the rotor screw and tighten with a wrench before

further operation.

Overloading rotors

The maximum load of the rotor and the maximum speed have been established

by the manufacturer. Do not attempt to exceed these values. The maximum

speed of the rotor has been measured for liquids having a homogeneous density

of 1.2g/ml or less. In order to centrifuge liquids with a higher density it is

necessary to reduce the speed. Failure to reduce the speed may result in

damage to the rotor and centrifuge. The revised maximum speed can be

calculated with the following formula:

Reduced speed (n

red

)

x max speed (n

max

)

Example:

Where the density of the liquid is 1.7, the new maximum speed would be

calculated as follows:

n

red

=

x 14,000 = 9,882 rpm

If in doubt concerning maximum speeds, please contact the manufacturer for

assistance.

Operation

ATTENTION: Never attempt to operate the centrifuge with rotors or

adapters that show signs of corrosion or mechanical damage.

Never centrifuge strongly corrosive materials that may damage the

rotors or accessories.

Closing the lid

After the rotor has been properly secured and loaded, close the centrifuge lid,

making sure that the interlock has been engaged.

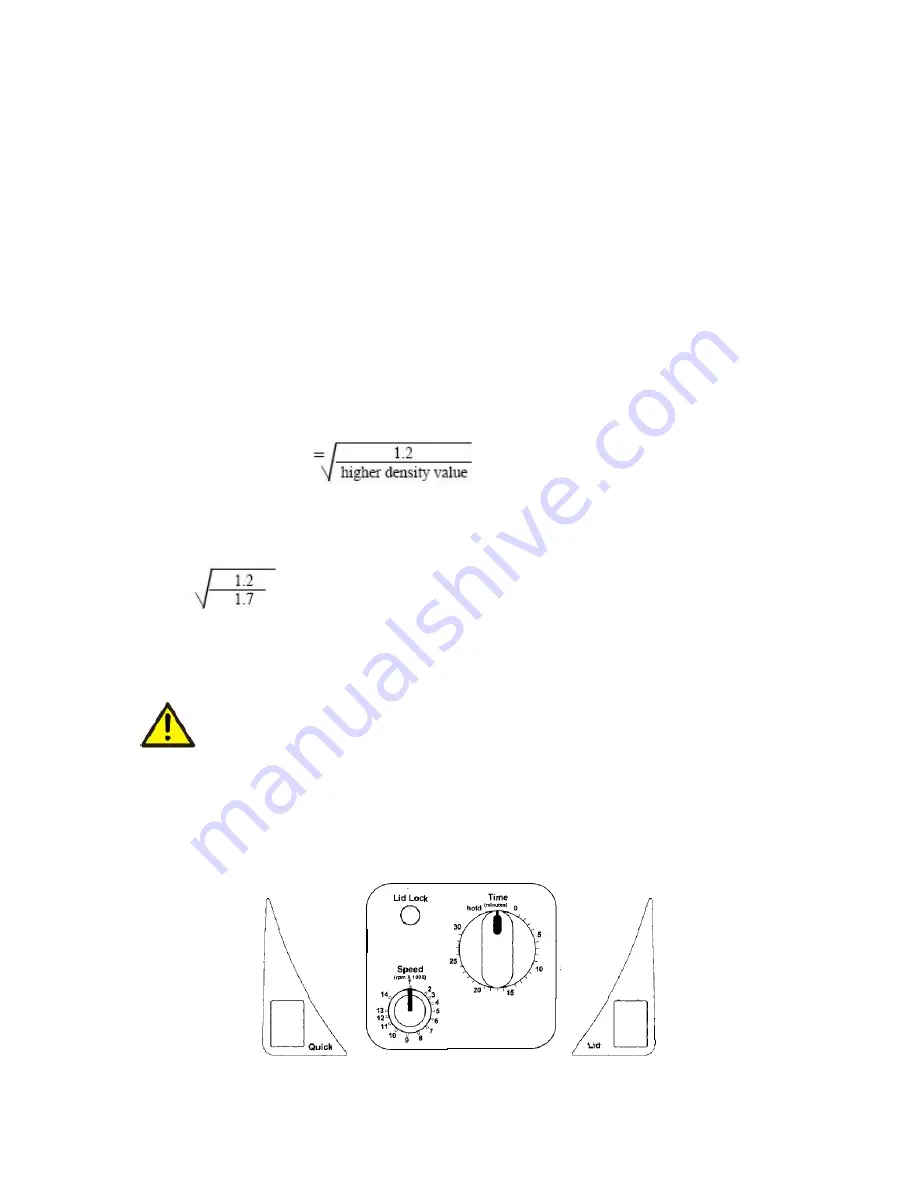

Figure 4. Spectrafuge 16M Control panel layout